ItemNo :

LITH-18650PVCMOQ :

1Place of Origin:

ChinaColor :

optionalPort :

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 days

1.1 Equipment Application

l Designed for stripping the outer casing of 18650 cylindrical batteries.

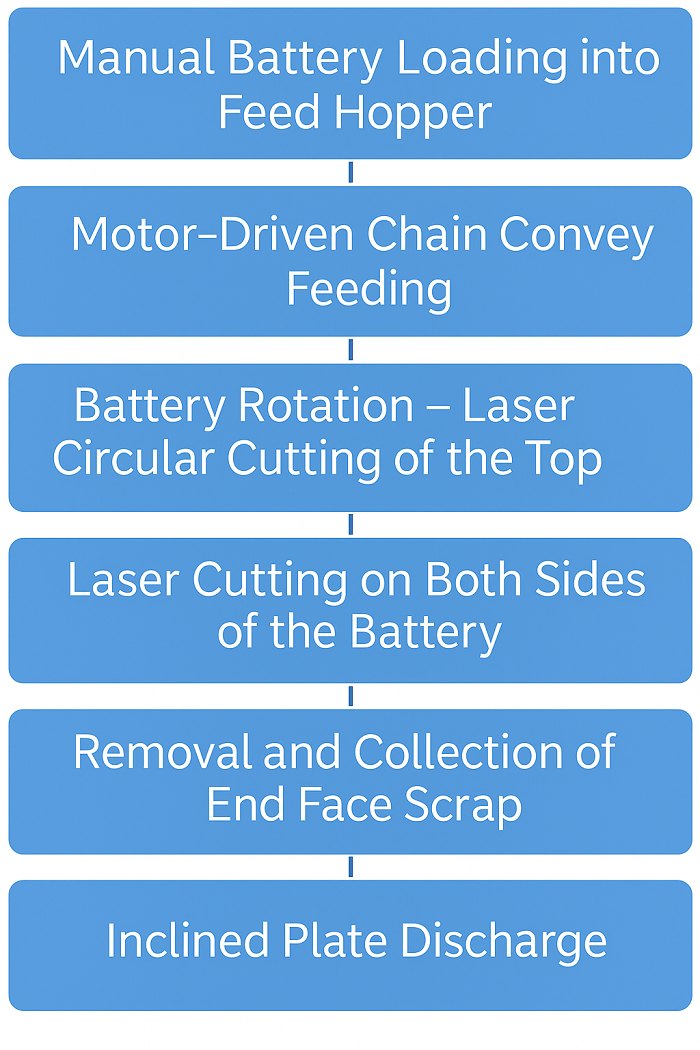

1.2 Equipment Operation Flow

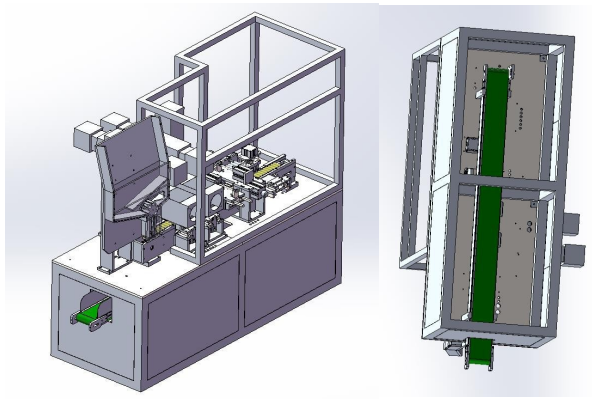

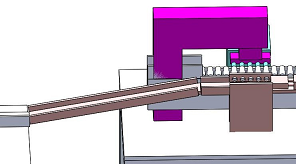

1.3 Equipment Diagram

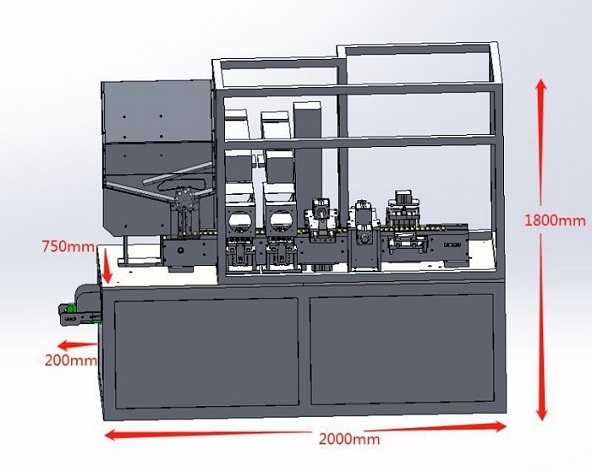

Overall Dimensions

l Laser Stripping Unit: 2000 mm × 750 mm × 1800 mm (L × W × H)

l Automatic Boxing Unit: 1000 mm × 700 mm × 1800 mm (L × W × H)

l Note: Dimensions are subject to the actual equipment.

Equipment Weight

l Total weight: approx. 1000 kg

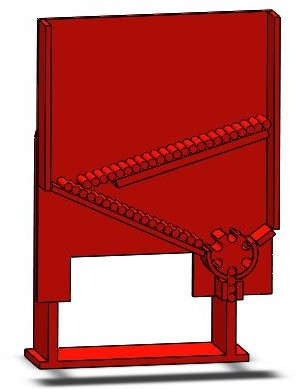

1.4.1 Manual Battery Loading into Feed Hopper

l Operator places batteries into the hopper; a feed wheel dispenses batteries into the chain conveyor.

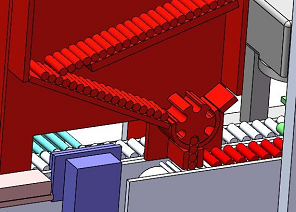

1.4.2 Motor-Driven Chain Conveyor

l Stepper motor drives the chain to feed batteries one by one.

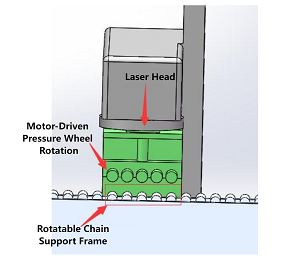

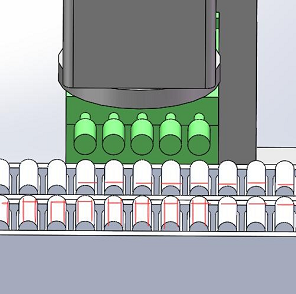

1.4.3 Laser Circumferential Cutting of Battery Heads

l Pressing mechanism holds the battery and rotates it; laser beam cuts the heads of 5 batteries simultaneously.

1.4.4 Rotary Transfer Mechanism

l Mechanical arm grabs 5 batteries, reorients them, and places them onto the second chain conveyor.

1.4.5 Dual-Side Laser Cutting

l Laser beam cuts two straight lines on each battery, centered on the body.

l Two parallel chain tracks enable simultaneous head cutting and side cutting.

1.4.6 End-Face Scrap Removal Mechanism

l Cylinders push 5 batteries into the scrap removal unit, where heads are clamped;

rear cylinders push batteries back to the track, discarding the head scrap;

scraps are collected in a bin under the workbench.

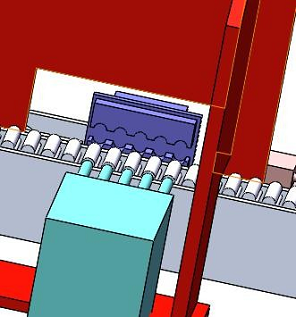

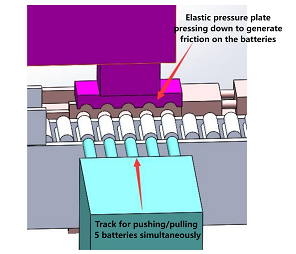

1.4.7 Steel Shell and Outer Film Separation

l Rubber plates position batteries top and bottom, increasing friction;

steel shell is pushed out for separation, leaving waste film on the track;

waste is carried down with the chain and collected in a bin under the workbench.

1.4.8 Inclined Plate Discharge

l Separated steel shells are discharged via a 1000 mm long inclined plate.

1.4.9 Automatic Boxing

l Automatically loads processed batteries into collection boxes.

1.4.10 Laser Section Enclosure with Exhaust Fan

l Laser cutting section is enclosed and equipped with exhaust ventilation.

2.1 Supported Product Specifications

l 18650 cylindrical battery (Diameter: 18 mm, Height: 65 mm)

2.2 Process Documents

l As provided by Party A.

3.1 Performance Parameters

1. Efficiency: >60–80 PPM

2. Equipment uptime rate: ≥99% (equipment-related downtime only)

3. First-pass yield: ≥99% (equipment-related defects only)

4. Automatic counting function included

5. Material collection position provided; layout optimized for single-operator use

6. Stripped batteries must have no appearance defects

3.2 General Parameters

Item

Content

Remarks

Appearance Color

As per Party A’s provided color sample

—

Operation Interface

Chinese

PLC + touchscreen

Equipment Noise

≤70 dB at 1 mm from outer wall

Material-related noise (e.g., peeling) excluded

Safety Standards

Refer to GB5662.1

Mechanical and electrical protection requirements

HC Series CO₂ Laser Machine

Product Specifications

Weight: 45 kg

Laser Power: 30 W

Laser Wavelength: 10.6 μm

Marking Area: 110 × 110 mm

Marking/Scanning Speed: 5,000–20,000 mm/s

Input Voltage: 220 V / 50 Hz / 5 A

Total Power Consumption: 350 W

Cooling Method: Air cooling

Protection Rating: IP54

1. Compressed Air Pressure: 0.4–0.8 MPa (4–8 kgf/cm²), flow ≤50 L/min

2. Dust Collection: Equipment supplied with dust collector to collect peeling waste; clean regularly

3. Ambient Temperature: 20–50 °C

4. Relative Humidity: 5–55% RH

5. Cleanroom Level: ≥ Class 100,000; no corrosive, explosive, or flammable gases or liquids present

Power Supply: Single-phase AC 220 V, 50 Hz; voltage fluctuation ≤ ±10%; power consumption 2.5 kVA

I. Equipment Overview

1.4 Main Module Descriptions

II. Applicable Materials and Product Specifications

III. Equipment Specifications

IV. On-Site Environment Requirements (Provided by Party A)

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +8618659217588

+8618659217588 18659217588

18659217588