- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-DS150MOQ :

1Delivery Time:

5 days

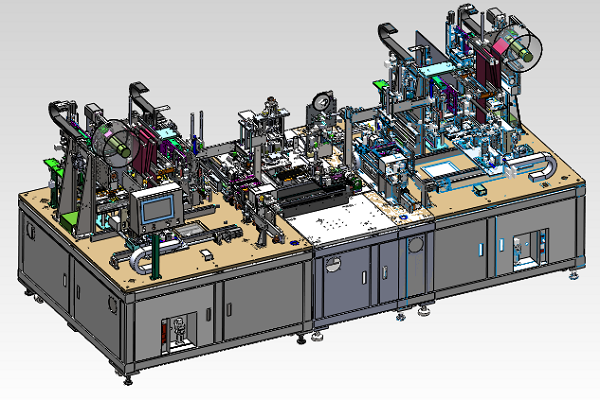

Dual-Workstation Automatic Z-Type Stacking Machine for Prismatic Lithium-ion Power Battery Cells

1. Equipment Introduction

1.1 Equipment Overview

This equipment is mainly used for the Z-shaped stacking process of prismatic lithium-ion power battery cells.

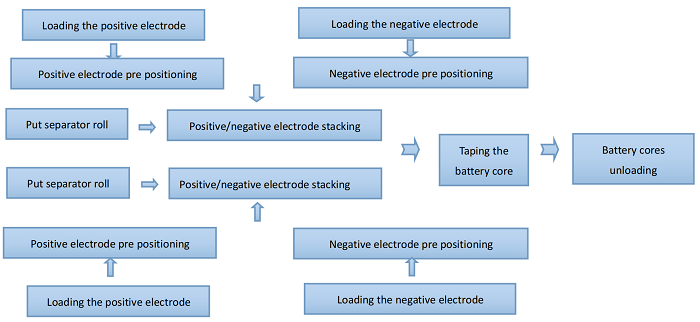

1.2 Workflow

The separator is actively unwound, routed through the tension control system, and guided onto the stacking platform. The platform then moves the separator back and forth to create the proper alignment for electrode placement. The stacking process commences with the positive and negative electrode sheets: two robotic suction arms retrieve these sheets from their respective left-hand feed boxes, position them with pinpoint accuracy, and stack them onto the platform. Once stacking is complete, the separator is cut to length. A robotic arm transfers the cell to the taping station, where taping is carried out automatically—all while the next cell’s stacking cycle begins without interruption.

1.3 Equipment Features

· 1.3.1 Separator: Active unwinding; tension control; deviation correction; static elimination; alignment accuracy ±0.5mm.

· 1.3.2 High precision: Mechanical positioning of electrode sheets ensures total stacking accuracy within ±0.3mm.

· 1.3.3 High efficiency: Single-side stacking speed reaches 1.2s–1.5s/Pcs depending on sheet size.

· 1.3.4 Dust protection: Effective dust protection mechanisms are installed at material box and pre-alignment positions.

· 1.3.5 Reliability: All high-precision and frequently moving modules are fixed with positioning pins.

· 1.3.6 Multi-sheet & missed sheet protection: Equipped with anti-multiple sheet mechanism and detection system to prevent stacking errors.

· 1.3.7 Tab inspection: Prevents inclusion of faulty electrode sheets with bent or missing tabs.

· 1.3.8 Stacked-cell discharge

2. Standard Components

|

No. |

Component Name |

Qty/Set |

Description |

|

1 |

Automatic Material Feeder |

4 |

Special insert-type feed boxes; 2 sets for both positive and negative sheets |

|

2 |

Auxiliary Feeding Unit |

4 |

Brushes, vibration, air blow, dust removal, anti-multi-sheet |

|

3 |

Lifting Unit for Feeding |

2 |

Ensures reliable sheet pickup; alarms for sheet shortage |

|

4 |

Separator Tension Mechanism |

2 |

Active unwinding with constant tension |

|

4.1 |

Separator Deviation Correction |

2 |

Roll deviation correction |

|

5 |

Pre-positioning Module |

4 |

Mechanical positioning with dust suction system |

|

5.1 |

Multi-sheet Detection |

4 |

Ultrasonic thickness detection |

|

6 |

Stacking Robot Arm |

4 |

Servo-driven, reliable sheet pickup and placement |

|

7 |

Suction Cup Assembly |

8 |

2 vacuum nozzles + 2 suction plates for each type |

|

8 |

Stacking Platform |

2 |

Servo-driven with ball screw linear motion |

|

9 |

Cell Transfer Arm |

1 |

Automatically transfers cells |

|

10 |

Separator Cutting Unit |

2 |

Thermal cutters; < 3mm distance to cell edge |

|

11 |

Side Taping Unit |

1 |

Configurable for tab areas and four sides |

|

12 |

Cell Discharge Mechanism |

1 |

Stacked discharge |

|

13 |

Control Panel |

1 |

Touch screen with emergency/power buttons |

|

14 |

Internal Control System |

1 |

All electrical/pneumatic inside enclosure |

|

15 |

Frame Panel |

2 |

Color: computer white |

|

16 |

Dustproof Cover |

1 |

Aluminum alloy + acrylic, with safety interlock |

|

17 |

Dust Collection |

1 |

Blower system at feed and pre-alignment stations |

|

18 |

Vacuum System |

/ |

Provided by manufacturer |

3. Material Specifications

3.1 Material Dimensions

|

Material |

Form |

Length (mm) |

Width (mm) |

Thickness (um) |

ID (mm) |

Max OD (mm) |

|

Cathode |

Sheet |

50-160 |

30-150 |

100-280 |

- |

- |

|

Anode |

Sheet |

50-160 |

30-150 |

80-280 |

- |

- |

|

Cathode Tab |

- |

10-40 |

10-60 |

12-30 |

- |

- |

|

Anode Tab |

- |

10-40 |

10-60 |

6-20 |

- |

- |

|

Separator |

Roll |

- |

60-250 |

16-45 |

76.2 |

300 |

|

Tape |

Roll |

20-80 |

10-20 |

100-200 |

76.2 |

150 |

Notes:

1. Electrode length refers to tab direction only (excluding tab).

2. No obvious powder loss, edge waviness or burrs < 15um; punching tolerance < 0.2mm.

3. No obvious warping, deformation or adhesion.

4. Separator serpentine deviation: ±0.2mm/1000mm.

3.2 Cell Specifications

|

Item |

Specification |

Cell Diagram |

||

|

Length L |

50-160 mm |

|

||

|

Width W |

30-150 mm |

|||

|

Thickness T |

3-20 mm |

|||

|

Tab Exposure L1 |

6-30 mm |

|||

|

Tab Orientation |

Opposite |

|||

|

L + L1 (tab side limit) |

≤200 mm |

|||

|

|

|

|||

4. Technical Parameters

|

Item |

Value |

|

Single-side stacking time |

1.2 - 1.5s |

|

Auxiliary time per cell |

≤10s |

|

Sheet-to-separator accuracy (adjacent) |

±0.5mm |

|

Separator edge alignment |

±0.4mm |

|

Sheet-to-sheet alignment |

±0.3mm |

|

Overall stack accuracy |

±0.3mm |

|

Stackable layers |

Within thickness limits |

|

Discharge method |

Cell stack discharge |

|

Machine utilization rate |

≥95% (machine-side) |

|

Qualification rate |

≥98% (machine-side) |

5. Standard Components List

|

No. |

Component |

Brand |

|

1 |

Cylinder |

AIRTAC |

|

2 |

Linear Rail |

DINGHAN/HIWIN |

|

3 |

Ball Screw |

TBI/HIWIN |

|

4 |

PLC |

OMRON |

6. Format Change Parts List

|

No. |

Module |

Part Name |

Unit |

Qty |

Notes |

|

1 |

Electrode box |

Movable panel |

pcs |

8 |

Adjustable range for feeder box, pre-alignment, suction |

|

2 |

Pre-position |

Adjustment plate |

pcs |

4 |

|

|

3 |

Stack arm |

Suction plate |

pcs |

4 |

|

|

4 |

Stack platform |

Compression plate |

pcs |

8 |

|

|

5 |

Cell support plate |

pcs |

2 |

||

|

6 |

Discharge |

Bracket |

pcs |

4 |

|

|

7 |

Tape Unit |

- |

set |

1 |

|

|

8 |

Others |

|

|

|

|

7. Wearing Parts List

|

No. |

Name |

Model |

Manufacturer |

Remarks |

|

1 |

Nozzle |

Custom |

Machined Part |

Daily cleaning required |

|

2 |

Plate 1 |

Custom |

Machined Part |

10-day lead time |

|

3 |

Plate 2 |

Custom |

Machined Part |

10-day lead time |

|

4 |

Vacuum Filter |

VFD-3-06 |

CHELIC |

Weekly cleaning required |

|

5 |

Vacuum Generator |

VAB-0706 |

CHELIC |

Weekly cleaning required |

|

6 |

Foam |

- |

Consumable |

Protects contact surface with cell |

|

7 |

Teflon |

- |

Consumable |

Protects contact surface with electrode |

8. Delivery List

|

No. |

Item |

Qty |

Unit |

Remarks |

|

1 |

Automatic Stacker |

1 |

unit |

Model for acceptance |

|

2 |

Solenoid Valve |

1 |

pcs |

Spare part |

|

3 |

Sensor |

2 |

pcs |

Spare parts |

|

4 |

Tools |

1 |

set |

Tool kit |

|

5 |

Delivery Specification |

1 |

copy |

After signing; return 1 copy |

|

6 |

Quality Inspection Report |

1 |

copy |

Provided on delivery |

|

7 |

User Manual |

1 |

copy |

Provided on delivery |

|

8 |

Spare Parts List |

1 |

set |

Delivered with equipment |

|

9 |

Format Change Materials |

1 |

set |

Delivered with equipment |

|

10 |

Wearing Parts List |

1 |

copy |

Includes models and part numbers |

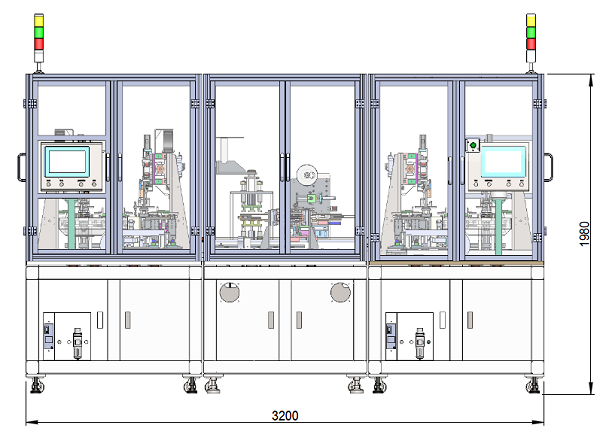

9. General Machine Specifications & Diagram

|

Item |

Specification |

|

Machine Size |

W3870 x L1950 x H1900mm (final design size) |

|

Weight/Floor Load |

~2200KG; >450Kg/m^2 |

|

Power Supply |

AC220V ±10%, Single Phase, 7KW, 50Hz |

|

Compressed Air |

0.5~0.7MPa, 200L/min, dry air |

|

Temperature/Humidity |

5~35℃; 5~55% |

|

Air/Dust |

No corrosive/toxic gas; no conductive dust |

|

Magnetic/Vibration |

No magnetic field interference or strong vibrations |

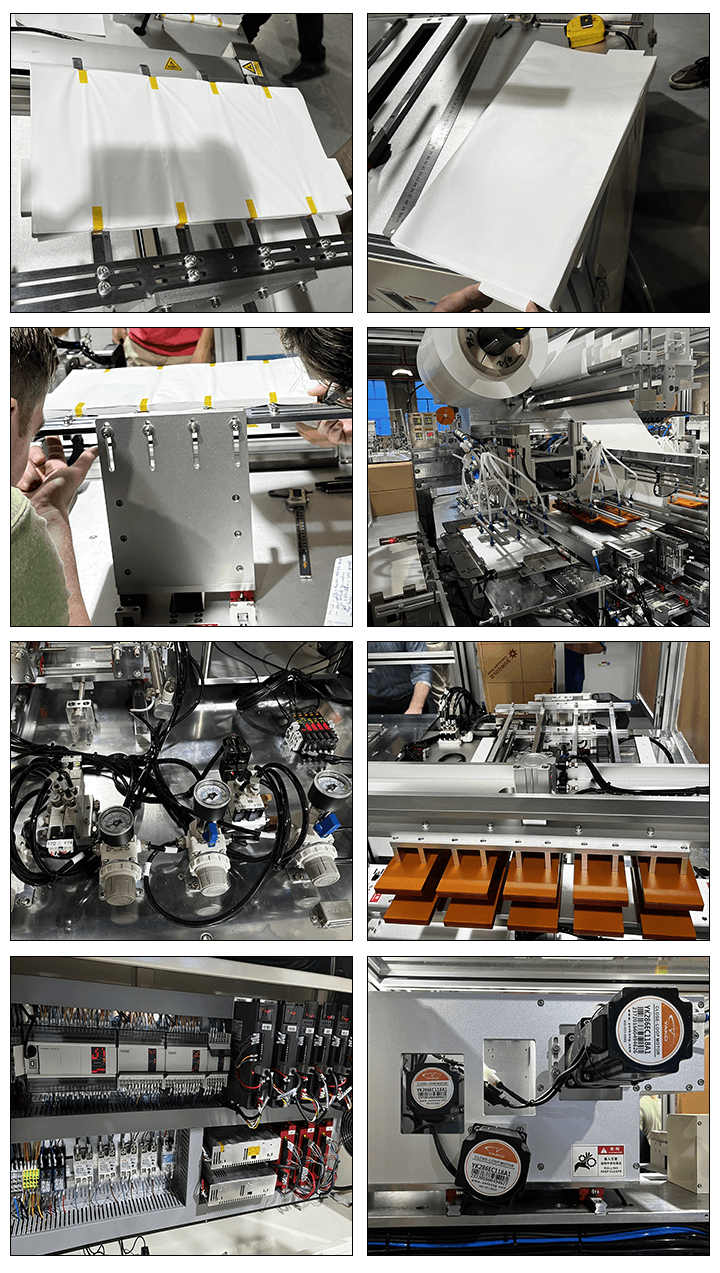

Production Assembly Plant

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588