Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Perovskite Solar Cell Assembly Line: Overview, Components, Processes, and Optimization

A perovskite solar cell assembly line is a specialized production system designed to automate the manufacturing of perovskite solar cells (PSCs) at scale. This assembly line integrates various processes, from material preparation to final encapsulation, ensuring high throughput, uniformity, and cost-effectiveness in producing PSCs. The goal is to transition this emerging technology from laboratory-scale fabrication to industrial-scale deployment.

In this article, we will explore the concept, components, processes, and optimization strategies for a perovskite solar cell assembly line.

●What Is a Perovskite Solar Cell Assembly Line?

A perovskite solar cell assembly line refers to an automated or semi-automated system that combines multiple stages of PSC fabrication into a streamlined workflow. It includes equipment for depositing layers, treating materials, assembling devices, and testing performance. The assembly line ensures consistent quality, scalability, and efficiency in mass-producing perovskite solar cells.

●Key Components of a Perovskite Solar Cell Assembly Line

A typical perovskite solar cell assembly line consists of the following components:

1. Material Preparation

Chemical Synthesis Units: Prepare precursor solutions for perovskite materials.

Solution Mixing Systems: Ensure precise mixing of solvents and precursors.

Gloveboxes: Provide controlled environments free from moisture and oxygen for handling sensitive materials.

2. Layer Deposition Systems

Spin Coaters: Deposit thin films of perovskite or other solution-based materials onto substrates.

Slot Die Coaters: Enable continuous deposition of perovskite layers on flexible substrates.

Spray Coaters: Suitable for large-area deposition with high uniformity.

Vacuum Deposition Systems: Used for depositing electron transport layers (ETLs), hole transport layers (HTLs), and metal electrodes.

Examples: Sputtering systems, thermal evaporators, atomic layer deposition (ALD).

3. Thermal Treatment Systems

Oven Annealers: Crystallize perovskite films under controlled temperature conditions.

Rapid Thermal Processors (RTP): Facilitate fast and uniform heating for improved film quality.

Vacuum Furnaces: Provide inert or vacuum environments for thermal treatments.

4. Encapsulation Systems

Laminating Machines: Seal solar cells between barrier films to enhance stability.

Vacuum Sealing Systems: Ensure airtight seals to protect against environmental degradation.

5. Testing and Characterization Systems

Solar Simulators: Measure current-voltage (I-V) characteristics under standardized light conditions.

Quantum Efficiency Analyzers: Assess spectral response and external quantum efficiency (EQE).

- Electroluminescence (EL) Imaging Systems: Detect defects and non-uniformities in solar cells.

Environmental Chambers: Test durability under varying temperature, humidity, and UV exposure.

6. Automation and Control Systems

Robotics: Automate material handling, substrate transfer, and alignment processes.

Process Control Software: Monitor and optimize each step of the fabrication process for consistency and quality assurance.

●Perovskite Solar Cell Assembly Line Processes

The assembly line follows a sequential process to fabricate perovskite solar cells:

1. Substrate Preparation

Clean and pattern transparent conductive oxide (TCO) substrates such as fluorine-doped tin oxide (FTO) or indium tin oxide (ITO).

2. Electron Transport Layer (ETL) Deposition

Deposit the ETL using techniques like sputtering, ALD, or spin coating.

Common ETL materials include titanium dioxide (TiO₂), zinc oxide (ZnO), or tin oxide (SnO₂).

3. Perovskite Layer Deposition

Use solution-based methods (spin coating, slot die coating, spray coating) or vacuum-based methods to deposit the perovskite absorber layer.

Optimize composition and thickness for maximum efficiency.

4. Hole Transport Layer (HTL) Deposition

Deposit the HTL using spin coating, vapor deposition, or other suitable methods.

Common HTL materials include Spiro-OMeTAD, PEDOT:PSS, or copper(I) thiocyanate (CuSCN).

5. Metal Electrode Deposition

Deposit the top electrode using thermal evaporation or sputtering.

Common metals include gold (Au), silver (Ag), or aluminum (Al).

6. Encapsulation

Seal the solar cell with barrier films or glass to protect it from moisture, oxygen, and other environmental factors.

7. Testing and Quality Assurance

Perform electrical and optical characterization to evaluate device performance.

Conduct environmental testing to assess long-term stability.

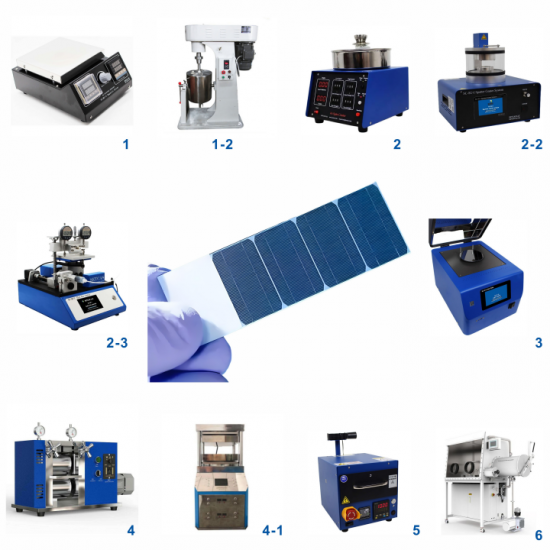

Solar Cell Research Equipment

●Optimization Strategies for Perovskite Solar Cell Assembly Lines

To maximize efficiency, reduce costs, and improve scalability, the following optimization strategies can be employed:

1. Scalability

Transition from batch processing to continuous roll-to-roll manufacturing for large-area substrates.

Use scalable deposition techniques like slot die coating or spray coating.

2. Uniformity

Implement advanced control systems to ensure consistent film thickness and quality across large areas.

Use in-line monitoring tools to detect and correct defects during fabrication.

3. Cost-Effectiveness

Optimize material usage by minimizing waste and recycling unused precursors.

Reduce energy consumption through efficient thermal treatment and automation.

4. Stability

Develop stable perovskite compositions and encapsulation techniques to enhance long-term performance.

Incorporate lead-free alternatives to address toxicity concerns.

5. Automation

Integrate robotics and AI-driven process control software to minimize human error and increase throughput.

Use predictive maintenance systems to reduce downtime and improve reliability.

6. Environmental Control

Maintain controlled environments (e.g., gloveboxes, humidity chambers) throughout the fabrication process.

Design systems to handle sensitive materials safely and prevent contamination.

●Challenges in Perovskite Solar Cell Assembly Lines

1. Material Sensitivity:

Perovskite materials are highly sensitive to moisture, oxygen, and heat, requiring precise environmental control.

2. Uniformity at Scale:

Achieving uniform film quality over large areas remains a significant challenge, especially for solution-based deposition methods.

3. Lead-Free Alternatives:

Developing environmentally friendly, lead-free perovskite materials without compromising efficiency is critical.

4. Encapsulation:

Designing effective encapsulation methods to ensure long-term stability under real-world conditions is essential.

5. Reproducibility:

Ensuring consistent performance across batches requires strict process control and standardization.

●Future Trends in Perovskite Solar Cell Assembly Lines

1. Roll-to-Roll Manufacturing:

Develop continuous roll-to-roll processes for producing flexible and lightweight perovskite solar cells on plastic substrates.

2. Lead-Free Materials:

Innovate new perovskite compositions that eliminate toxic elements like lead while maintaining high efficiency.

3. Tandem Solar Cells:

Integrate perovskites with silicon or other materials to create tandem solar cells with record-breaking efficiencies.

4. AI and Machine Learning:

Use AI-driven algorithms for process optimization, defect detection, and predictive maintenance in assembly lines.

5. Sustainability Focus:

Design assembly lines that minimize waste, reduce energy consumption, and promote environmentally friendly practices.

●Conclusion

Perovskite solar cell assembly lines are pivotal for scaling up the production of this promising photovoltaic technology. By integrating advanced equipment, automation, and process control, these lines enable the mass production of high-efficiency, stable, and cost-effective perovskite solar cells. Addressing challenges related to material sensitivity, uniformity, and scalability is essential for realizing the full potential of perovskite solar cells in the renewable energy market.

What advancements in perovskite solar cell assembly lines excite you most? Share your thoughts below! Together, let’s explore how these innovations are shaping the future of clean energy.

English ▼

English ▼ English ▼

English ▼ ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588