- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

DM-BeeWrapMOQ :

1Lead Date :

15 daysWarranty:

2yearsDelivery Time:

5 days

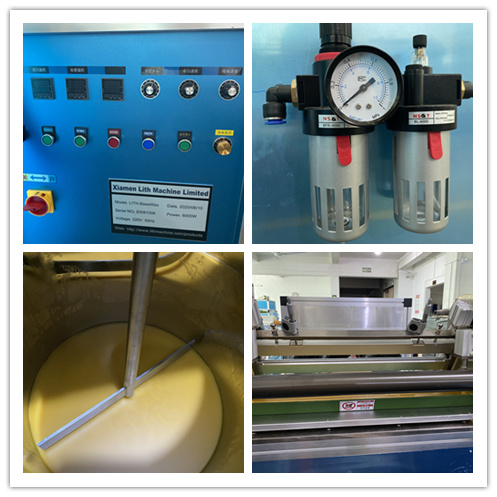

Functional description and technological process

1.1 Function description: This coater coats cotton fabric with beeswax oil, etc., and forms environmentally friendly packaging paper after curing in a drying oven.

1.2 Equipment technological process

1.2.1. Unwinding of coated substrate (tension control)→→Manual stop, cutting and reloading→→Drawing before coating→→Comma blade coating→→Reserved thickness measurement installation location→→2m guide roller oven →→Deviation deviation at the oven exit→→Laminating unit→→Drawer roll discharge

1.2.2. Compound unwinding (overall edge correction)→→Manual cutting and replacement→→Laminating unit

1.2.3. Laminating unit →→Rewinding and cutting piece (optional)

Basic Parameters

|

Control system |

self-developed PLC touch screen |

|

Coating width |

100-1000mm (customizable) |

|

Coating method |

Doctor blade |

|

Drying method |

Air-cooled dry |

|

Cooling oven length |

|

|

Temperature |

normal temperature ~120 degrees |

|

Coating speed |

0-5 meters/min ((customizable)) |

|

Tension control |

Automatic tension |

|

Winding device(optional) |

Automatic winding |

|

Cutter(optional) |

Flat cutter |

|

Heated cylinder |

30L |

|

Power supply |

220V, 50/60Hz, 5000W |

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588