- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-XY-350MOQ :

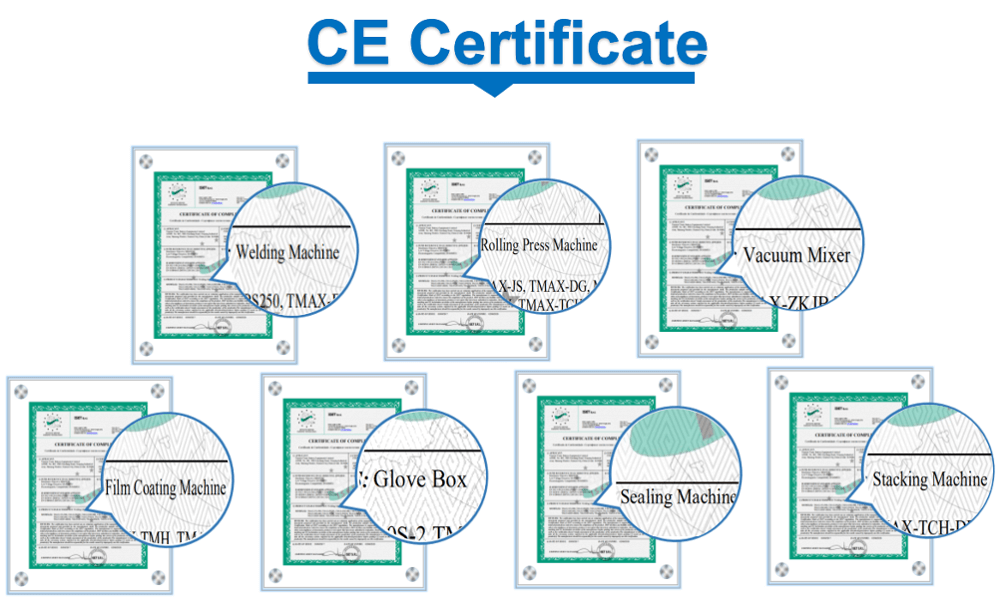

1Compliance:

CEWarranty:

2 yearsDelivery Time:

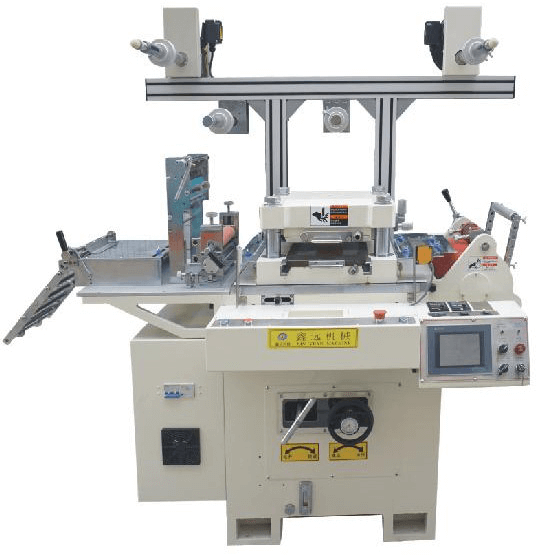

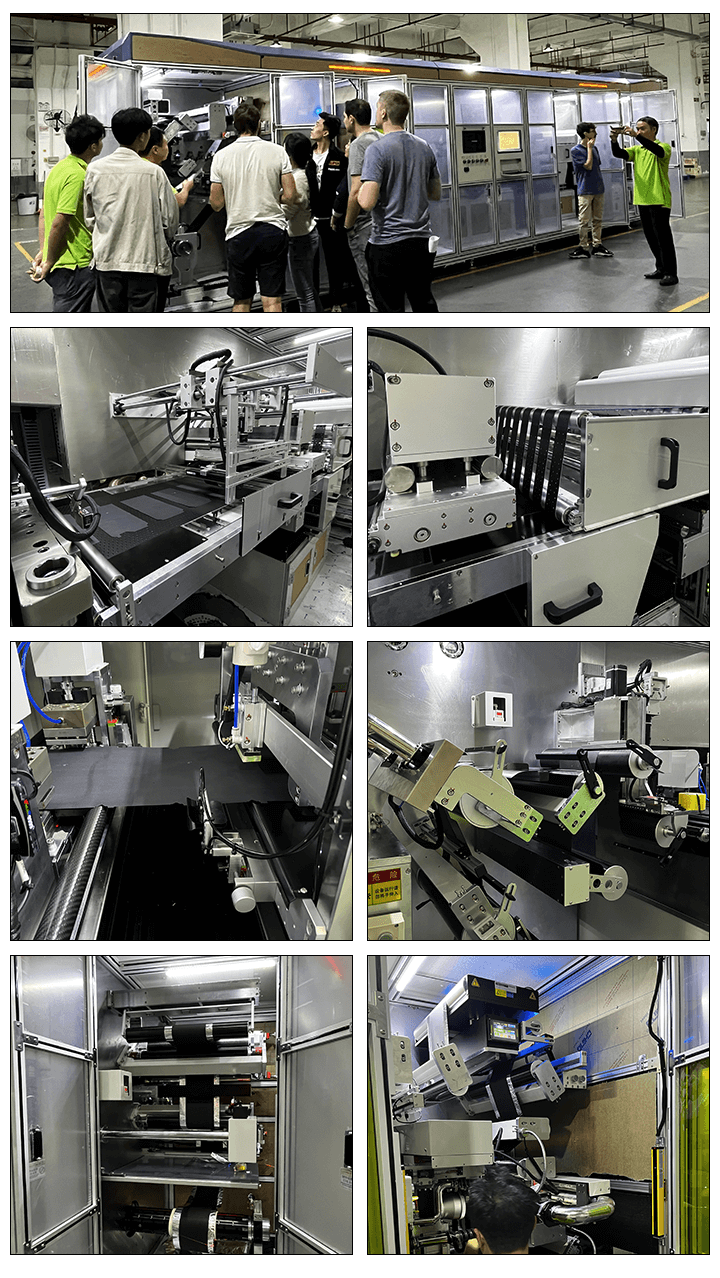

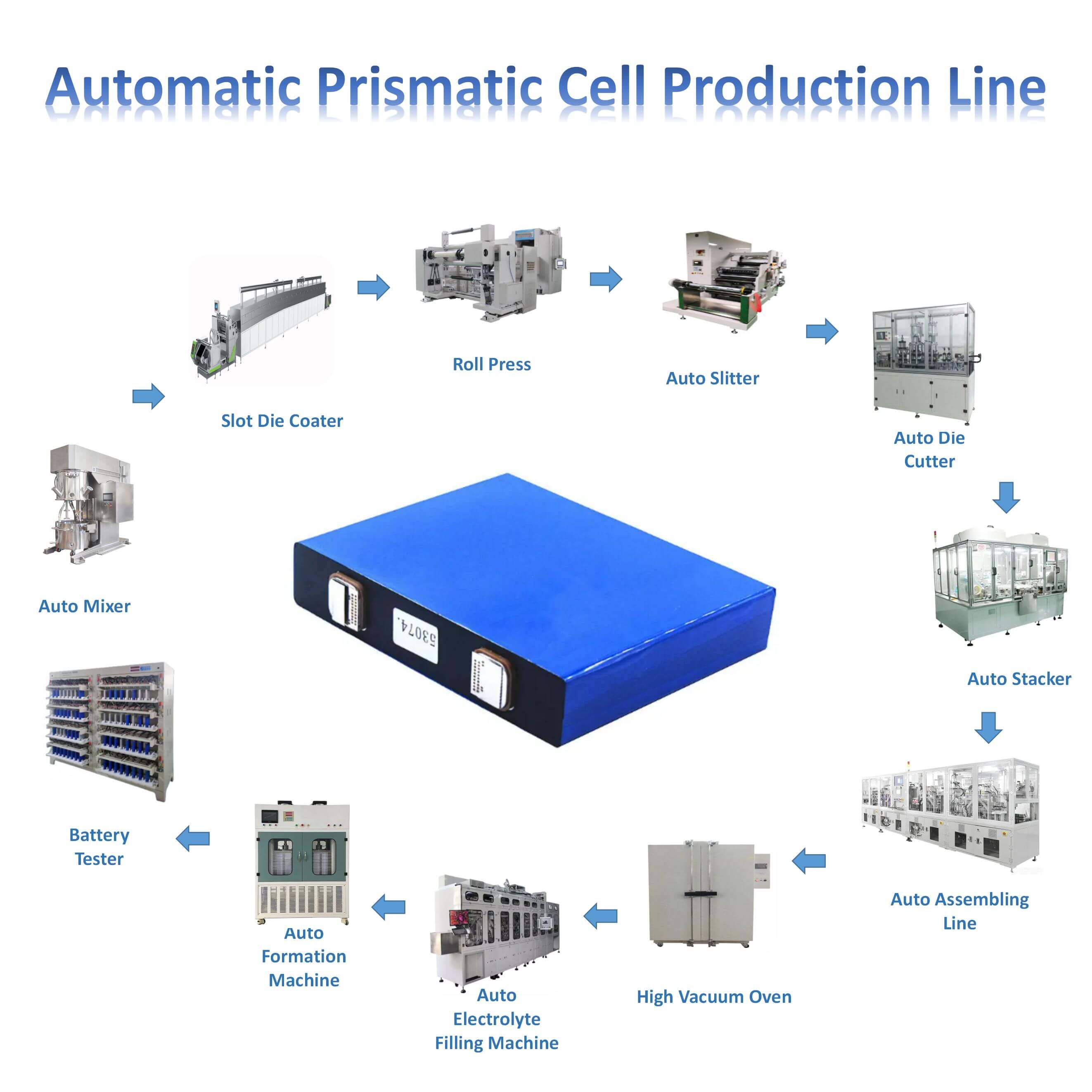

5 daysAutomatic Double Servo Battery Electrode Die Cutter Machine For Prismatic Cell Production

The die cutter is mainly used for pouch cell electrode sheet cut for stacking pouch cell/polymer battery. It is a necessary tool in the production line of pouch cell to produce specific shapes of cathodes and anodes.

Application range:

Adhesive products, backlight, dust screen, copper foil, aluminum foil, protective film, PE, pet, optical film, black-and-white adhesive, frame adhesive, single and double-sided adhesive, Mylar, foam and other materials.

Main Features

1.Adopt advanced computer digital drawing system, double servo drive, PLC program control, touch screen operation, fast die cutting speed and high efficiency.

2. Overall design:

① the feed frame adopts the fine adjustment device to make the adjustment more convenient and quick;

② stainless steel plates are used for die-cutting parts, material inlet and outlet and feeding frame, and scale is corroded to make the material easier to adjust. The machine has the advantages of high precision, low noise and high speed;

④ driven by servo main motor, stamping is more stable and power saving.

3. Die cutting part:

① installable: carving mold, wood mold, rubber mold, corrosion mold, hardware mold;

② it can easily realize automatic punching for many times, with high accuracy of nesting;

③ it can be thrust fully or thrust half;

④ equipped with mirror light curtain safety protection device to ensure the safety of operators;

4. Automatic oil supply system to ensure the service life and stability of the machine;

5. It can be used online with laminating machine, slicing machine and other equipment.

SPECIFICATIONS

|

Machine model |

XY-350 |

|

Template area |

350*305mm |

|

Maximum material width |

360mm |

|

Die cutting speed |

18000p/h |

|

Adjustable stroke |

±3mm |

|

Applicable tool die |

Board mold, rubber mold, AB mold, carving mold, hardware mold |

|

Drawing accuracy |

±0.1mm |

|

Pressure accuracy |

±0.02mm |

|

Power |

4.8KW |

|

Voltage |

380V |

|

Machine weight |

1800KG |

|

Machine size (length, width and height) |

1950*1300*1800mm |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588