- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-ZTH-05MOQ :

1Delivery Time:

5 days

Automatic Combined Die Cutting And Stacking Equipment For Lithium Prismatic Cell

Feature

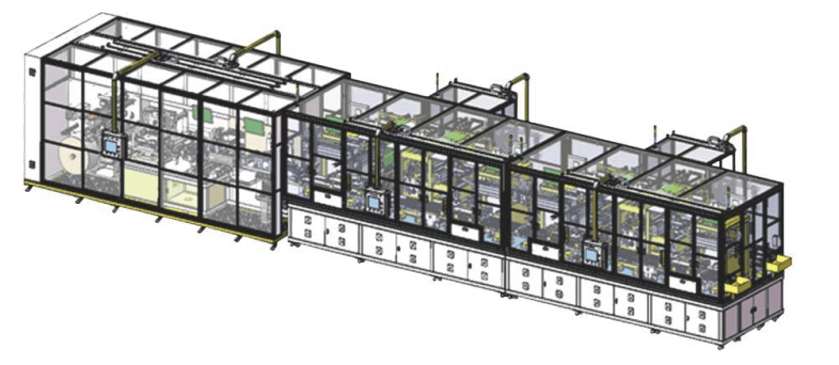

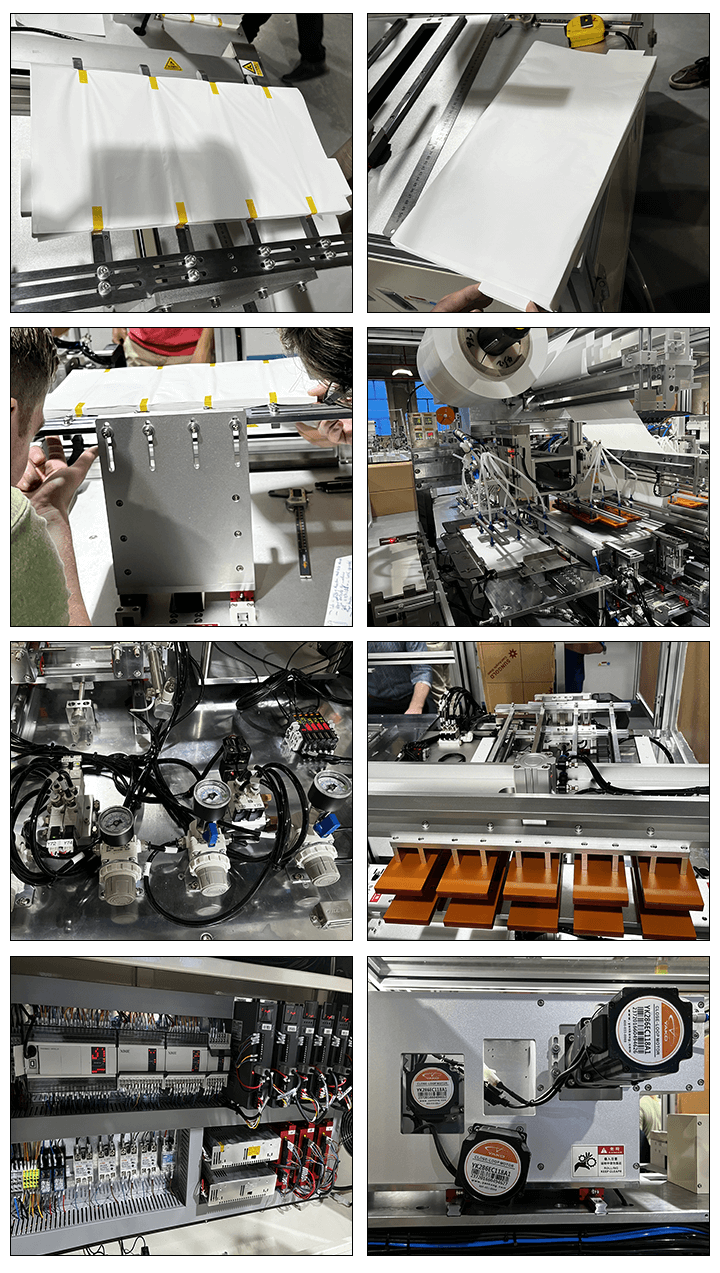

This equipment is mainly used for automatic unwinding, automatic deflection, tension control, CCD defect detection, driving, cutting and forming rounded corners, iron and dust removal, CCD size detection, NG rejection, vacuum belt conveying, CCD pre-positioning, diaphragm unwinding, stacking table according to the set number of layers into cores, diaphragm cutting and gluing, discharging, etc.; the final cores are loaded in pallets and can be Docking automatic logistics line and MES system, etc.

Specification

|

Project |

Parameters |

|

Positioning method |

CCD positioning |

|

Stacking efficiency |

Single station 0.6(whole machine 0.2)s/pcs |

|

Auxiliary time |

<10s |

|

Burr size |

Va≤12um ; Vbs12um |

|

Die life |

1. Can be used ≥ 1,500,000 times after each mold repair; 2. Mold can be repaired ≥ 10 times. |

|

Alignment accuracy between poles and diaphragm |

Centre deviation ±0.3mm |

|

Diaphragm end-face alignment accuracy |

±0.4mm |

|

Alignment accuracy between adjacent diaphragms |

±0.3mm |

|

Overall alignment accuracy |

King 0.5mm |

|

Number of laminations |

Settable within the thickness adaptation range |

|

Outer diaphragm |

No tail roll |

|

Die-cutting pass rate |

≥99.5% |

|

Qualified rate of laminations |

≥99.5% |

|

Overall machine qualification rate |

≥99% |

|

Cranking rate |

≥98% |

|

Dimension |

W13000mm x L5000mm x H2700mm |

|

Weight/load |

Approx. 35000Kg; >800Kg/M-2 |

|

Power supply |

AC380V three-phase;voltage fluctuation±10%;power:120KW;frequency:50Hz |

|

Compressed air |

0.5~0.7Mpa(5~7kgf/cm2),dosage 3000L/min |

|

Item |

Specification |

|

|

Punching method |

Hardware Die Punching |

|

|

Material system |

Continuous coated pole rolls with formed pole lugs |

|

|

Roll diameter |

≤∮800mm |

|

|

Inner diameter of reel |

3"/6" |

|

|

Pole winding error |

士2mm |

|

|

Serpentine bend error |

1mm/m |

|

|

Difference in height of wavy edge |

<2mm |

|

|

Thickness T |

5~20mm |

|

|

Width W |

80~200mm |

|

|

Length L |

120~300mm |

|

|

Length L1 of the tabs |

10~30mm |

|

|

Orientation of the tabs |

Ipsilateral/heterolateral |

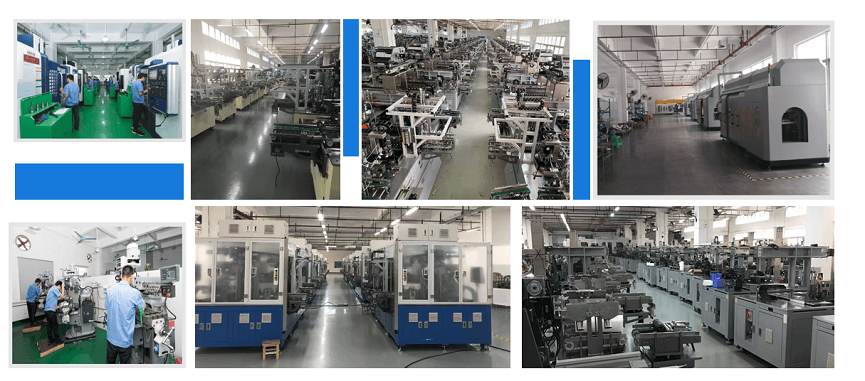

Production Assembly Plant

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588