ItemNo :

LITH-SS200MOQ :

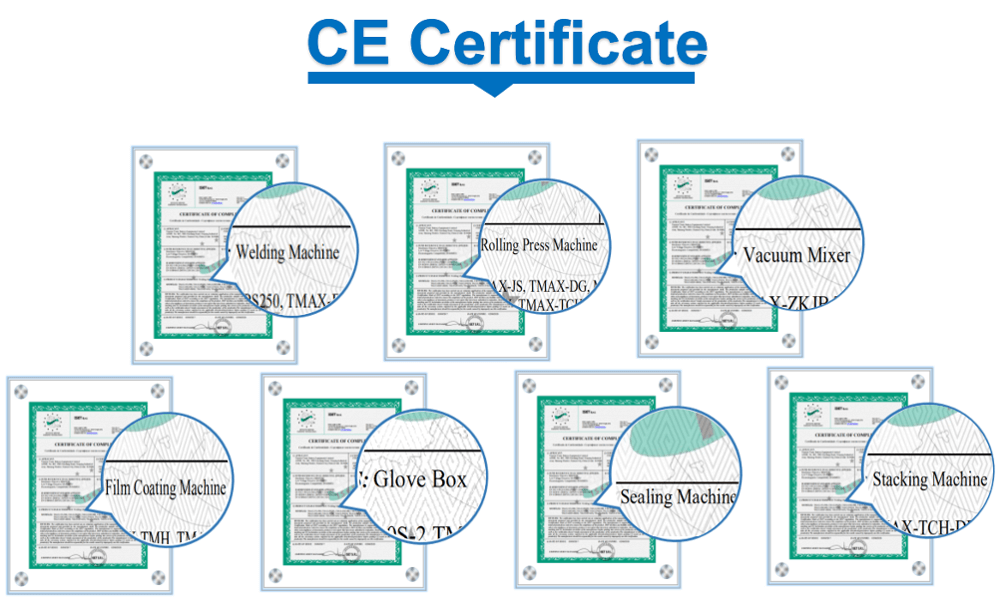

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com200-Type Automatic Stacking Machine with CCD Alignment and Tail-Wrap for Lithium-Ion Cells

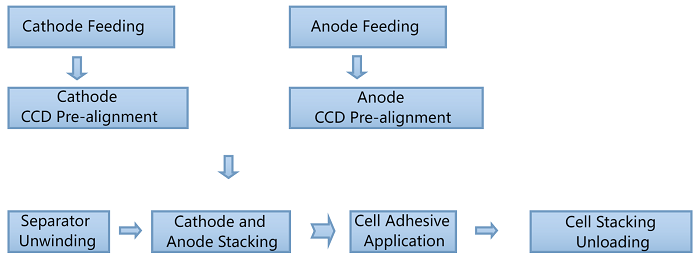

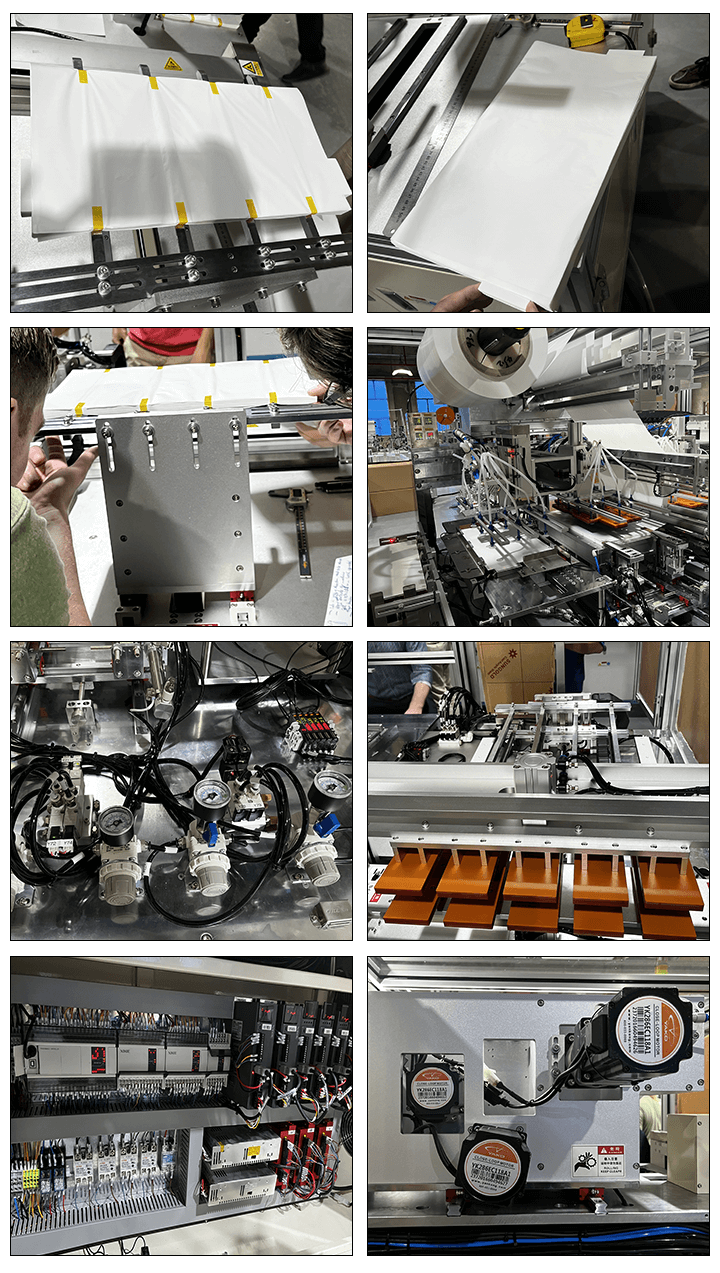

The separator is actively unwound and fed through a tension mechanism into the stacking platform. The platform moves the separator back and forth to position the electrode sheets. Two robotic arms with suction cups pick up the positive and negative electrodes from two hoppers on the left side. Using CCD visual positioning, the robotic arms accurately stack the electrodes onto the platform. After stacking, the machine performs automatic tail wrapping (switchable to tail-free mode), cuts the separator, transfers the cell to the taping station, and automatically applies adhesive tape. The next cell stacking process then begins.

1. Dimensions: 1700mm (L) × 2350mm (D) × 1900mm (H) (final dimensions subject to design)

2. Power: 220V, 50Hz

3. Air Source: 0.5 MPa

4. Environment: Non-corrosive gas/liquid, non-explosive gas

5. Color: Supplier’s standard (International Warm Grey 1C)

1. Applicable Size:

Length: 150–300mm

Width: 100–200mm

Thickness: 5–20mm

Tab Length Q ≤ 35mm

2. Speed: 1.5–1.6 s/pcs

3. Binding Method: Automatic tail wrapping and taping

4. Electrode-to-Separator Alignment Accuracy: Center deviation ±0.3mm

5. Dust Protection: Effective dust-proof mechanisms on hoppers and CCD pre-alignment units

6. Reliability: High-precision and frequently moving modules are secured with locating pins

7. Multiple Sheet/Missing Sheet Protection: Includes CCD-assisted positioning and ultrasonic thickness detection. Alarms and stops when multiple or no sheets are picked, effectively preventing stacking errors.

|

Item |

Spec |

Remarks |

|

|

Cell Length (L) |

150–300 mm |

|

|

|

Cell Width (W) |

100–200 mm |

||

|

Cell Thickness (T) |

5–20 mm |

||

|

Tab Exposure (L1) |

10–35 mm |

||

|

Tab Direction |

Same Side |

||

|

L + L1 (Opposite Side Tabs) |

≤ 370 mm |

||

|

|

|

||

|

No. |

Component |

Qty |

Description |

|

1 |

Electrode Auto Feeder |

2 |

Insert-type hoppers; one for positive and one for negative |

|

2 |

Electrode Feeding Assistant |

2 |

Brushes, vibration, air blowing, dust suction, anti-multiple feeding |

|

3 |

Electrode Lifting Unit |

2 |

Ensures reliable pickup; auto stop and alarm when out of material |

|

4 |

Separator Tension Unit |

1 |

Active unwinding with constant tension |

|

4.1 |

Separator Alignment System |

1 |

Automatic alignment during unwinding |

|

5 |

CCD Pre-positioning Module |

2 |

Precision visual alignment |

|

5.1 |

Multiple Sheet Detection |

2 |

Ultrasonic detection to prevent multiple sheets |

|

6 |

Stacking Robotic Arms |

2 |

Servo driven; automatic pick-and-place |

|

7 |

Suction Cup Units |

4 |

Vacuum nozzles and suction plates |

|

8 |

Stacking Platform |

1 |

Servo-driven linear and vertical motion via precision ball screw |

|

9 |

Separator Air Blower |

1 |

Blows separator to the opposite side |

|

10 |

Cell Transfer Robotic Arm |

1 |

Transfers cell to taping position |

|

11 |

Separator Cutting Mechanism |

1 |

Thermal cutting blade for length-based separation |

|

12 |

Tape Application Unit |

1 |

Tapes four sides (including between tabs), adjustable position & number, tape width 8–15mm |

|

13 |

Auto Unloading Unit |

1 |

Auto stacking for batch removal |

|

14 |

Electrical Operation Interface |

1 |

Touch screen, emergency stop, power switch |

|

15 |

Control System |

1 |

Internal electric & pneumatic system, space-saving, easy maintenance |

|

16 |

Frame Base |

2 |

Color: computer white |

|

17 |

Dustproof Cover |

1 |

Aluminum alloy and acrylic, with interlocks and emergency stop |

|

18 |

Dust Suction System |

1 |

Blower suction at hopper |

|

19 |

Vacuum System |

/ |

Requires customer-supplied compressed air |

|

No. |

Name |

Brand |

Remarks |

|

1 |

Cylinder |

AIRTAC |

|

|

2 |

Linear Guide |

DINGHAN |

|

|

3 |

Ball Screw |

HIWIN |

|

|

4 |

PLC |

OMRON |

|

|

No. |

Module |

Part Name |

Unit |

Qty |

Remarks |

|

1 |

Electrode Hopper |

Movable Plate |

pcs |

2 |

Adjustable range for hopper, positioning, suction |

|

2 |

CCD Positioning |

Adjustment Plate |

pcs |

2 |

|

|

3 |

Stacking Robot |

Suction Plate |

pcs |

2 |

|

|

4 |

Stacking Table |

Compression Plate |

pcs |

4 |

|

|

5 |

|

Cell Support Plate |

pcs |

2 |

|

|

6 |

Unloading Module |

Support Plate |

pcs |

4 |

|

|

7 |

Taping Unit |

— |

set |

1 |

|

|

8 |

Others |

|

|

|

|

|

No. |

Name |

Model/Spec |

Manufacturer |

Remarks |

|

1 |

Suction Nozzle |

Custom |

Machined |

Daily cleaning required |

|

2 |

Compression Plate 1 |

Custom |

Machined |

10-day production cycle |

|

3 |

Compression Plate 2 |

Custom |

Machined |

10-day production cycle |

|

4 |

Vacuum Filter |

VFD-3-06 |

CHELIC |

Weekly maintenance |

|

5 |

Vacuum Generator |

VAB-0706 |

CHELIC |

Weekly maintenance |

|

6 |

Foam |

— |

— |

Protective adhesive on cell side |

|

7 |

Teflon |

— |

— |

Protective adhesive on electrode side |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975