- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-TP1500SMOQ :

1Warranty:

2 yearsDelivery Time:

5 days1500mL Vacuum Planetary Centrifugal Defoaming Mixer Machine with Two Containers for High Viscosity Material

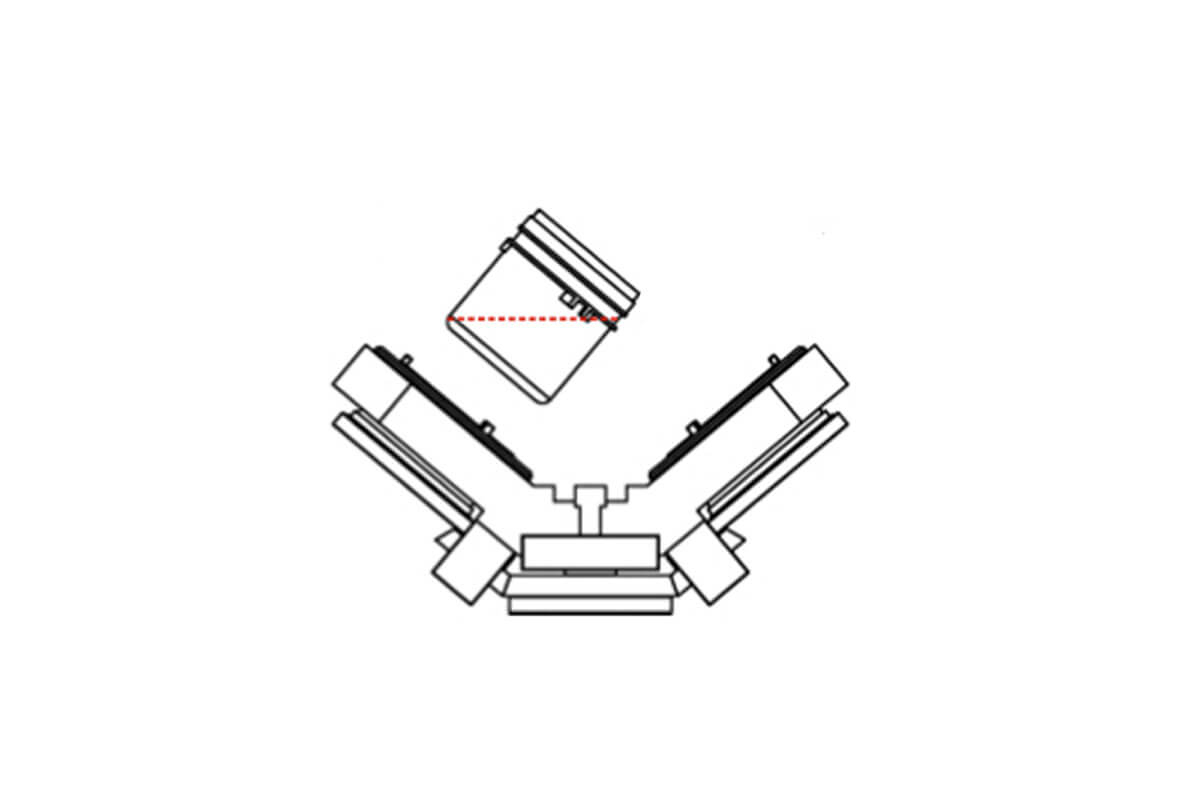

1: The material is evacuated while rotating and revolving in the container, and the mixing, dispersion and defoaming of high-viscosity materials can be realized in a few minutes.

2: Spiral bevel gear transmission: its stable and low-noise mechanical transmission. The machine has a low failure rate and a long life.

3: The overall boom is easy to maintain.

4: Rodless mixing is pollution-free and does not damage the material properties.

5: Standard machine 0~2000RPM, high speed and high efficiency. Special requirements can be customized up to 3000RPM machine.

6: Various fixtures can be customized according to customer requirements to meet customers' requirements for direct use of different packaging.

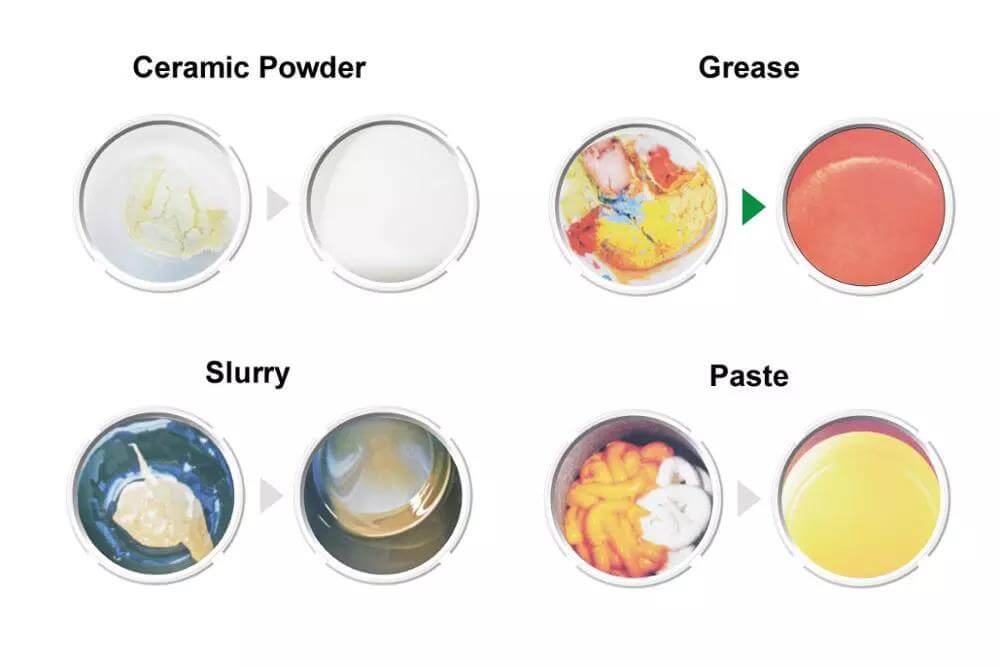

Applicable industries: semiconductor lighting (LED), photovoltaics, lithium batteries, capacitors, fine chemicals, etc.

Applicable materials: various particles (fluorescent powder, chemical powder, metal micro particles, etc.), liquid glue (silica gel, various adhesives, conductive glue, printing ink, etc.), metal paste (silver paste, aluminum paste, etc.).

Features introduction

1. Main shaft: Made of Swiss ASSAB S136 mirror die steel, after multiple heat treatments, the overall hardness reaches HRC62 degrees. The shaft is integrally ground, and the total runout does not exceed 1 wire. The sealing surface is then mirror-grinded to achieve a surface roughness of 0.02um mirror effect. The friction coefficient is extremely low, and the wear of the sealing ring due to its own super wear-resistant is minimal, and the high sealing performance of long life is realized. This is one of the magic weapons for many of our customers to maintain negative pressure above -98Kpa after several years of use.

2. Sealing ring: The ultra-wearable sealing ring of German Bayer company is adopted, and the wear resistance can reach a line speed of 40M/S. The line speed of our equipment is only 4M/S at 2000 rpm. The pressure can withstand 20KG/c㎡. This is the second magic weapon for many of our customers to maintain negative pressure above -98Kpa after several years of use.

3. Vacuum pump: a pump with forced oil circulation lubrication after adopting international advanced technology to improve, with good lubrication, low wear and long life. This is the third magic weapon for many of our customers to maintain negative pressure above -98Kpa after several years of use.

4. Gear wheel: adopts automobile spiral bevel gear structure, smooth running, low noise and long life.

5. Rotating arm: It adopts an integral rotating arm, which is all made of American imported aviation magnesium-aluminum 7075, which ensures the accuracy and stability of the product, and the center error is not more than ±0.02. The interchangeability is high, the machine arms of the same model can be interchanged at will, and the maintenance is convenient.

Specification parameter:

|

Name |

Vacuum centrifugal stirring defoaming machine |

|

Equipment type |

ITT-1500S (two cups) |

|

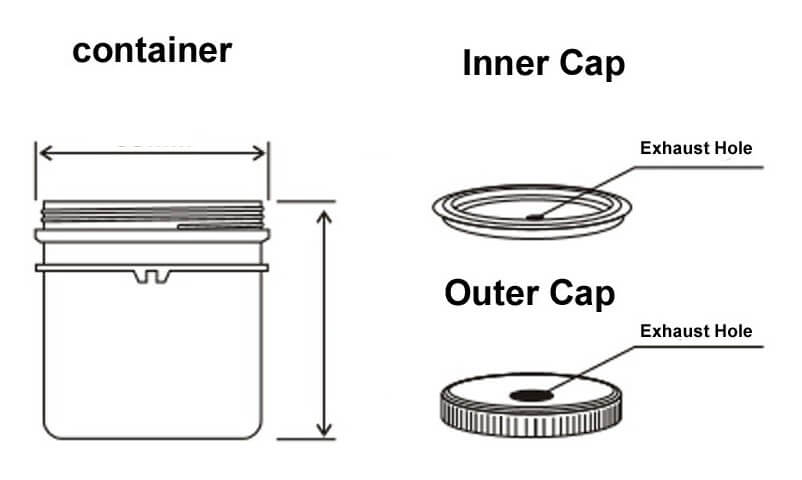

Container Capacity |

1500ml*2(Cup) |

|

The optimal capacity of mixing material |

100-900ml*1(Cup) |

|

Operation Type |

Human-machine Interactiom Mode |

|

Revolution Speed |

100-2000RPM |

|

Rotation Speed |

Invariablenes |

|

Vacuum |

240L/Minute,APROX.-98KPa |

|

Storage Program |

5 storage programs (each program can be set to five steps) |

|

Protection |

Door Cover,Breakdown, Overload |

|

Dimension (mm) |

585L*705W*800H |

|

Power,Voltage |

0.5-1.0KW,220V |

|

Weight |

Net Weight:150 KG |

|

Power Supply |

(Uniphase),AC220V.50-60Hz |

|

Clamp |

Option |

|

Syringe |

Max 50CC |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588