ItemNo :

LITH-SS150MOQ :

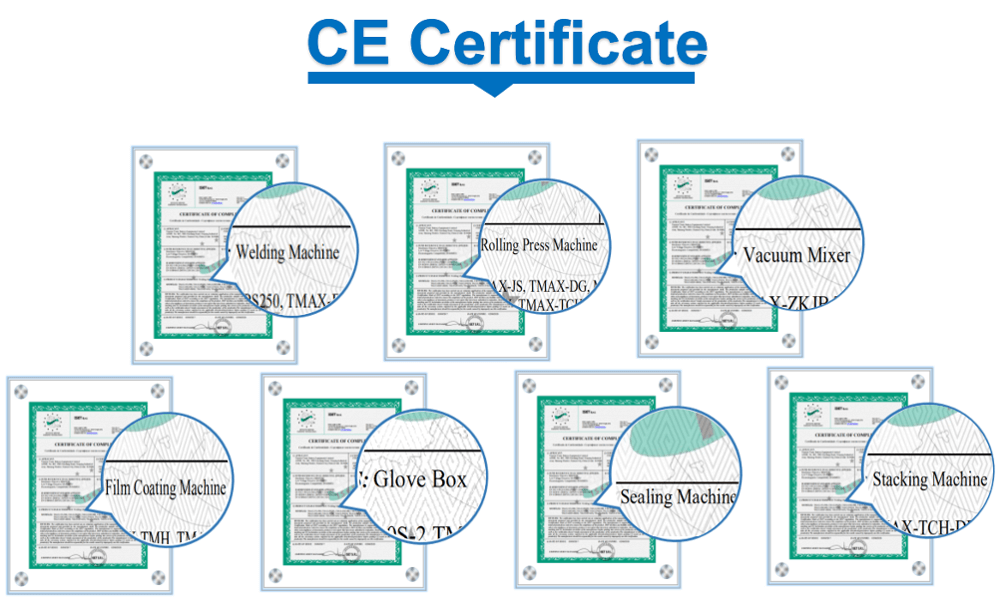

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com150-Type Single-Station Automatic Stacking Machine with Separator Cutting and Taping

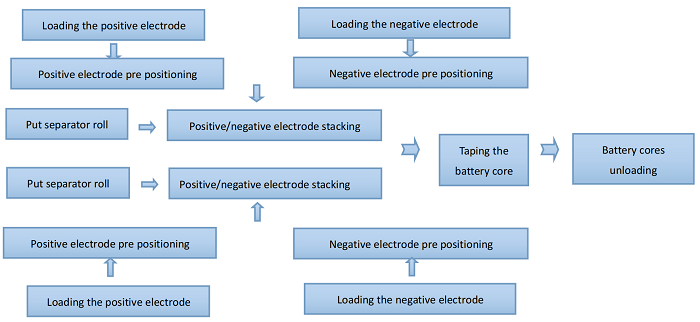

I. Function Overview

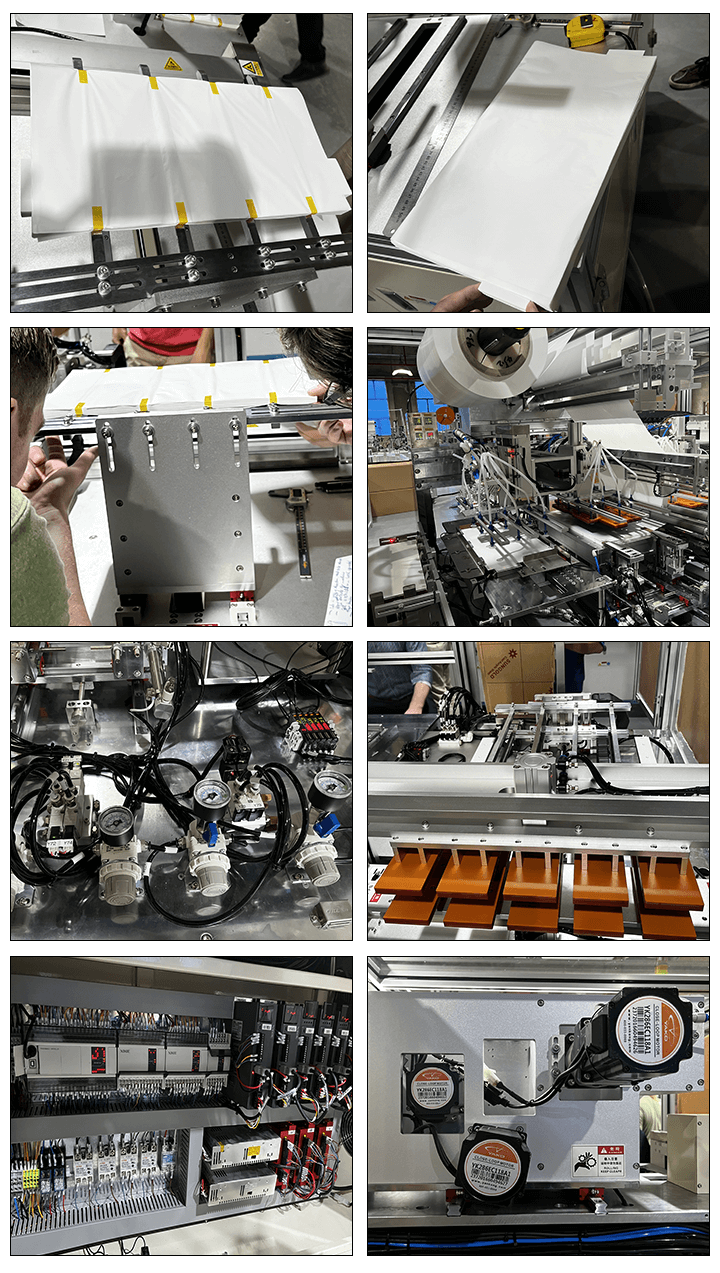

The separator is actively unwound and introduced into the stacking platform via a tension control mechanism. The stacking platform drives the separator to move reciprocally to enable electrode placement. The cathode/anode sheets are alternately stacked: two sets of robotic arms with suction cups respectively pick up the cathode and anode sheets from two material boxes on the left. After precise positioning, the sheets are stacked on the stacking platform. Once stacking is complete, the separator is cut, and the cell is transferred by a mechanical arm to the taping station for automatic tape application. Simultaneously, the next cell begins stacking.

II. Basic Parameters

1. Dimensions: 1940mm (L) × 1650mm (D) × 2100mm (H) (subject to actual design)

2. Power supply: 220V 50Hz

3. Air source: 0.5 MPa

4. No corrosive gases, liquids, or explosive gases

5. Color: Supplier standard (International Warm Gray 1C)

III. Technical Parameters

1. Applicable Cell Size: Length L135–190mm, Width W80–150mm, Thickness H3.5–20mm; Tab Length Q ≤25mm

2. Machine Speed: 1.4–1.6s/pcs

3. Electrode-to-Separator Alignment Accuracy: Center deviation ±0.25mm

4. Dust Protection: Effective dust-proof mechanisms installed on material box and pre-alignment areas

5. Reliability: High-precision, frequently moving modules are secured with positioning pins

6. Multi-sheet Missing Protection: Missing sheet detection; anti-multi-sheet mechanism; ultrasonic multi-sheet detection effectively prevents multiple sheets from being stacked into the cell

7. Tab Defect Detection: Detects tab bending, breaking, and edge defects to prevent defective sheets from entering the cell

Cell Specifications

|

Item |

Spec |

Remarks |

|

|

Cell Length (L) |

135–190 |

|

|

|

Cell Width (W) |

80–150 |

||

|

Cell Thickness (T) |

3.5–20 |

||

|

Tab Exposure (L1) |

10–25 |

||

|

Tab Direction |

Opposite Side |

||

|

When Tab Opposed |

L+L1 ≤ 180 |

||

|

|

|

||

IV. Standard Composition

|

No. |

Component Name |

Qty |

Description |

|

1 |

Material Box Auto Feeder |

2 |

Special insert-style box; two each for cathode/anode; adjustable range |

|

2 |

Electrode Sheet Feeder Aid |

2 |

Brush, vibration, air-blow, and dust collection; anti-multi-sheet |

|

3 |

Sheet Lifting Mechanism |

2 |

Ensures reliable sheet pickup; alarms when out of material |

|

4 |

Separator Tension Unit |

1 |

Active unwinding with constant tension |

|

4.1 |

Separator EPC System |

1 |

Web guiding for unwinding |

|

5 |

Mechanical Pre-Alignment |

2 |

Mechanical precision alignment; dust collection; vacuum system |

|

5.1 |

Multi-Sheet Detection |

2 |

Ultrasonic thickness detection to prevent multiple sheet stacking |

|

6 |

Stacking Robot Arm |

2 |

Servo-driven for reliable stacking; servo-driven material pickup |

|

7 |

Pickup Suction Mechanism |

4 |

Two sets of vacuum nozzles and suction plates |

|

8 |

Stacking Platform |

1 |

Servo-driven lift and shift using precision ball screw |

|

9 |

Separator Blowing Unit |

1 |

Blows separator to opposite side |

|

10 |

Cell Transfer Gripper |

1 |

Transfers cell automatically |

|

11 |

Separator Cutting Unit |

1 |

Hot cutting blade; cuts separator to set length |

|

12 |

Side Taping Unit |

1 |

Applies tape around all four sides including tab region; programmable |

|

13 |

Auto Discharge Unit |

1 |

Auto cell stacking for batch removal |

|

14 |

Electrical Operation System |

1 |

Touchscreen control with emergency stop, power switch, etc. |

|

15 |

Control System |

1 |

Electrical and pneumatic systems integrated inside equipment |

|

16 |

Machine Frame |

2 |

Color: PC White |

|

17 |

Dustproof Enclosure |

1 |

Aluminum-glass cover with interlock switch and emergency stop |

|

18 |

Dust Collection Unit |

1 |

Blower-type suction; applied to pre-alignment and material box |

|

19 |

Vacuum System |

— |

Vacuum generator |

V. Main Component Configuration

1. Standard Parts List

|

No. |

Name |

Brand |

Remarks |

|

1 |

Cylinder |

AIRTAC |

|

|

2 |

Linear Guide Rail |

DINHAN / HIWIN |

|

|

3 |

Ball Screw |

TBI / HIWIN |

|

|

4 |

PLC |

OMRON |

|

2. Changeover Parts List

|

No. |

Assembly |

Part |

Unit |

Qty |

Remarks |

|

1 |

Electrode Box |

Adjustable Plate |

pcs |

4 |

Adjustable range for material box, pre-alignment, suction cup

|

|

2 |

Pre-Alignment |

Alignment Plate |

pcs |

2 |

|

|

3 |

Stacking Robot Arm |

Suction Plate |

pcs |

2 |

|

|

4 |

Stacking Platform |

Stacking Press Plate |

pcs |

4 |

|

|

5 |

Cell Support Plate |

pcs |

1 |

||

|

6 |

Discharge Unit |

Discharge Support |

pcs |

2 |

|

|

7 |

Taping Mechanism |

— |

set |

1 |

|

|

8 |

Others |

— |

— |

— |

|

3. Wearing Parts List

|

No. |

Name |

Model/Spec |

Manufacturer |

Remarks |

|

1 |

Suction Nozzle |

Custom |

Machined |

Clean daily |

|

2 |

Press Plate 1 |

Custom |

Machined |

10-day lead time |

|

3 |

Press Plate 2 |

Custom |

Machined |

10-day lead time |

|

4 |

Vacuum Filter |

VFD-3-06 |

CHELIC |

Clean weekly |

|

5 |

Vacuum Generator |

VAB-0706 |

CHELIC |

Clean weekly |

|

6 |

Foam |

— |

— |

Protective layer for cell contact |

|

7 |

Teflon |

— |

— |

Protective layer for electrode contact |

4. Delivery List

|

No. |

Item |

Qty |

Unit |

Remarks |

|

1 |

Automatic Stacking Machine |

1 |

Set |

Acceptance Model |

|

2 |

Solenoid Valve |

1 |

Piece |

Spare |

|

3 |

Sensor |

2 |

Piece |

Spare |

|

4 |

Tool Kit |

1 |

Set |

Tools |

|

5 |

Technical Specification Sheet |

1 |

Copy |

Provided after contract signing |

|

6 |

Shipment QC Report |

1 |

Copy |

Provided at delivery |

|

7 |

User Manual |

1 |

Copy |

Provided at delivery |

|

8 |

Spare Parts (and List) |

1 |

Set |

Provided at delivery |

|

9 |

Changeover Parts (and List) |

1 |

Set |

Provided at delivery |

|

10 |

Wearing Parts List |

1 |

Copy |

Includes part numbers and drawings |

|

11 |

Wiring Diagram |

1 |

Set |

Provided after 90% payment and acceptance |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975