- Language:

English ▼

English ▼

Innovations in Pouch Cell Production line: Driving Efficiency and Performance in Lithium-ion Batteries

Introduction:

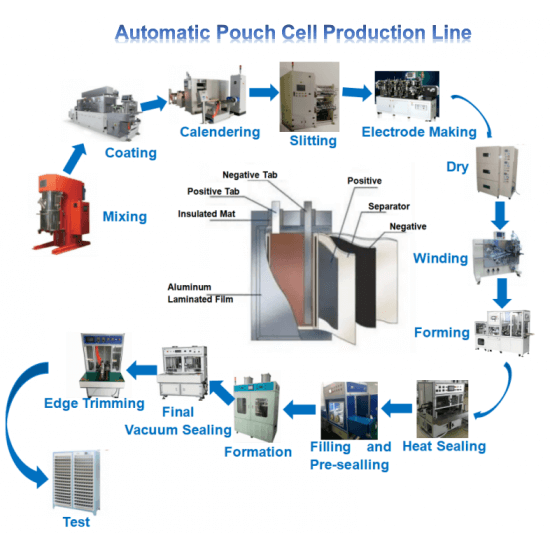

The evolution of lithium-ion battery technology has been propelled by continuous advancements in pouch cell production equipment. Pouch cells, recognized for their flexibility and versatility, have become integral components in various applications, from consumer electronics to electric vehicles. This article explores the cutting-edge technologies integrated into pouch cell production equipment, underscoring their pivotal role in shaping the landscape of battery manufacturing.

1. Coating Machines for Precise Electrode Application:

Modern pouch cell production begins with advanced coating machines designed for the precise application of electrode slurry onto current collectors. These machines ensure uniformity in coating thickness, optimizing energy density and enhancing overall battery performance.

2. Calendering and Compaction Systems:

State-of-the-art roll press machines play a crucial role in electrode calendering and compaction. These machines provide enhanced control over the thickness and density of coated electrodes, resulting in improved mechanical integrity and longevity of pouch cells.

3. Precision Stacking and Winding Technologies:

Efficient assembly is achieved through precision stacking and winding technologies. Small stacking machines precisely align coated electrodes and separators, while tabletop winding machines facilitate the formation of a tightly wound jelly roll configuration. These advancements contribute to the structural robustness of pouch cells.

4. Injection Molding for Seamless Encapsulation:

The encapsulation of pouch cells has undergone a paradigm shift with the integration of injection molding technology. Compact injection molding machines efficiently encase wound electrode stacks in pouch-shaped housings, streamlining the production process and allowing for greater design flexibility.

5. Formation Chambers for Optimal Performance:

Pouch cell production equipment now features advanced formation chambers designed for controlled charging and discharging cycles. These chambers play a critical role in optimizing electrochemical processes, leading to stabilized performance and enhanced overall efficiency.

6. Integrated Testing and Quality Control Systems:

Quality control is prioritized through integrated testing systems. Pouch cell production equipment includes real-time monitoring for voltage, capacity, and impedance, ensuring that each cell meets stringent quality standards throughout the manufacturing process.

7. Environmental Controls and Sustainability Measures:

Modern pouch cell production equipment incorporates environmental controls and sustainable practices. These measures aim to minimize the environmental impact of the manufacturing process, aligning with global sustainability goals.

Conclusion:

Innovations in pouch cell production equipment signify a transformative era in lithium-ion battery manufacturing line. These advancements not only enhance efficiency and performance but also contribute to the sustainability of energy storage solutions. As the demand for lithium-ion batteries continues to surge, the ongoing evolution of pouch cell assembly line remains at the forefront of technological progress in the energy storage industry.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588