ItemNo :

LITH-GT-9000FLMOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

2 daysEmail :

Louis@lithmachine.com

9000 m³/h NMP Solvent Recovery System

This series of NMP recovery systems utilizes the miscibility of NMP and water to recover exhaust gases emitted from coating machines. The system operates fully automatically, ensuring operational stability and safety. It adopts a three-stage spray absorption design, and the tail gas emission is significantly below the national emission standards. The system includes: ventilation ducts, recovery towers, pump groups, blower, NMP liquid storage tank, and control system. The unit features a high recovery rate, low operating cost, compact and aesthetic design, small footprint, excellent performance, and ease of operation—suitable for various lithium battery production lines during the coating process.

1. Air Volume Capacity: 9000 m³/h

Complies with GB 30484-2013 "Emission Standard of Pollutants for Battery Industry" regarding total non-methane hydrocarbon (NMHC) emissions.

2. Main Unit Color: SUS gray.

3. NMP Recovery Equipment Functional Modules:

|

No. |

Module |

Function Description |

|

1 |

Recovery Tower |

Recovers NMP vapor and ensures emission compliance through water spray absorption. |

|

2 |

Pump Group |

Circulates water within the recovery tower and discharges liquid. |

|

3 |

Blower |

Delivers air into the recovery tower and maintains positive pressure in the coater. |

|

4 |

Storage Tank |

Stores recovered NMP waste liquid. |

|

5 |

Electrical Control System |

Enables automation between the recovery system and coating machine, stabilizing oven concentration and meeting discharge standards. |

4. Delivery List:

|

No. |

Equipment Name |

Model |

Qty |

Remarks |

|

1 |

Recovery Tower |

LITH-GT-9000FL |

1 set |

SUS304 |

|

2 |

Blower |

3KW |

1 unit |

Intelligent frequency control |

|

3 |

Control Box |

NMP4K-1 |

1 set |

Local + remote control |

|

4 |

Water Pump |

1.5KW |

3 units |

Chemical pipeline pumps |

|

5 |

Storage Tank |

2m³ |

1 unit |

SUS201 |

|

6 |

Discharge Pump |

0.35KW |

1 unit |

Corrosion-resistant pump |

5. Main Components of 9000 Air Volume NMP Recovery System:

|

No. |

Item |

Specification |

Qty |

Remarks |

|

1 |

Tower Body |

∅1.0m × H2.2m |

3 pcs |

SUS304 |

|

2 |

Corrugated Packing |

φ1.2m×20mm×3 layers×0.3mm |

3 sets |

SUS304 |

|

3 |

Wire Mesh Packing |

φ1.0m×20mm |

1 set |

SUS304 |

|

4 |

Water Pump |

1.5KW |

3 pcs |

Tank internal pumps |

|

5 |

Online Waste Liquid Concentration Meter |

CM-800α |

1 set |

TMAX |

|

6 |

Exhaust Fan |

4KW |

1 set |

Guangzhou XinFeng |

|

7 |

Frequency Converter |

4KW |

1 set |

V&T |

|

8 |

Control Cabinet |

- |

1 set |

Q235, outdoor cabinet |

|

9 |

Circulation Piping |

- |

1 set |

SUS304 |

|

10 |

Storage Tank |

2m³ |

1 set |

SUS201 |

|

11 |

Liquid Level Alarm |

- |

1 set |

TMAX |

|

12 |

Discharge Pump |

0.35KW |

1 unit |

Corrosion-resistant pump |

1. Compliant with national, industry, and local regulations, as well as client requirements. Ensures treated exhaust meets legal and project-specific standards.

2. Employs efficient, energy-saving, and practical treatment processes with the goal of low energy consumption, minimal investment, small footprint, and easy maintenance.

3. Major components and electrical systems use branded and reliable manufacturers.

4. No secondary pollution is generated during construction or operation.

|

No. |

Parameter |

Value |

|

1 |

Max Exhaust Treatment |

9000 m³/h |

|

2 |

Single Tower Size |

∅1.2m × H2.2m |

|

3 |

Power Supply |

380V / 3P / 50Hz |

|

4 |

Installed Power |

8.5KW (4.5KW circulation + 4KW fan) |

|

5 |

Operating Weight |

2 tons |

|

6 |

Floor Load Requirement |

500 KG/m² |

|

7 |

Recovery Efficiency |

≥99.6% |

|

8 |

NMP Recovered Concentration |

Adjustable from 80% to 90% |

|

9 |

Tail Gas Concentration |

<50 mg/m³ |

|

10 |

Soft Water Consumption |

≤0.05 m³/h |

|

11 |

Installation Dimension |

7m × 2m |

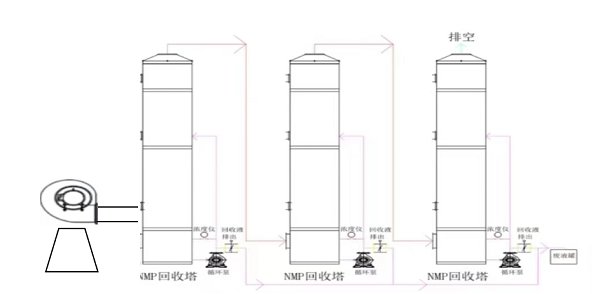

1. Process Diagram(Diagram for reference only)

1. Installation Render(Image for reference only)

1. The system recovers NMP from exhaust gases via pure water absorption. Waste gas enters from the bottom, where NMP dissolves in water or steam. After absorption, the gas-liquid mixture passes through a separator and then a rinsing unit to remove remaining NMP. As the waste gas is hot, an energy exchange occurs, causing partial evaporation of water. A circulation pump recycles liquid through the absorption unit, improving heat exchange efficiency and increasing recovered NMP concentration. After processing, exhaust can be discharged directly—essentially achieving zero emissions.

2. Tower Structure

The tower comprises three main zones:

Spray Heat Exchange Section: Enables rapid mass and heat transfer via direct contact between NMP vapors and water.

Mass Transfer Separation Section: Uses structured packing (140Y) for high-efficiency counter-current absorption.

Demisting Section: Captures mist through inertial impaction and swirl separation, with a demisting efficiency of 90–99%.

1. Electrical Panel Configuration

|

No. |

Component |

Brand |

Qty |

Remarks |

|

1 |

Electrical Parts |

Chint |

1 set |

|

|

2 |

Frequency Converter |

V&T |

1 set |

|

|

3 |

NMP Liquid Sensor |

Local |

1 set |

With lens cleaning device |

|

4 |

Valves |

Local |

1 set |

|

2. Control System Overview

|

No. |

Item |

Specification |

Remarks |

|

1 |

Main Control System |

Independent outdoor control cabinet, remote start/stop from coater head |

|

|

2 |

Operation Modes |

Manual, automatic, emergency stop, and remote start/stop |

|

|

3 |

Waste Liquid Concentration |

Display and configurable value |

|

|

4 |

Alarm Functions |

Sound and light alarm at coater head and outdoor buzzer alarm |

|

|

5 |

Safety Protection |

Over-temperature alarm and power-off protection |

|

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975