ItemNo :

LITH-WHFT-500MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

500mm Width Sodium-Ion Battery Electrode Slitting Machine With Roll to Roll Sytem

|

No. |

Item |

Technical Specifications |

Remarks |

|

1 |

Applicable Materials |

Electrode sheets after coating and calendaring: LFP, LCO, LMO, NCM, NCA, LTO, graphite, etc. |

|

|

2 |

Substrate Specifications |

Aluminum foil (AL): Thickness 9–30μm, Width 50–500mm, Max. roll diameter: 400mm |

|

|

Copper foil (Cu): Thickness 6–30μm, Width 50–500mm, Max. roll diameter: 400mm |

|

||

|

3 |

Roller Width Design |

650mm |

|

|

4 |

Guaranteed Slitting Width |

30–500mm |

|

|

5 |

Mechanical Running Speed |

50m/min |

|

|

6 |

Slitting Speed |

1–40m/min |

Depends on slitting quality |

|

7 |

Electrode Thickness Range |

70–250μm |

|

|

8 |

Slitting Method |

1. Combined rotary blade slitting; 2. Nishimura-type cutter structure; 3. Spec to be defined |

|

|

9 |

Rewinding Method |

Dual-shaft differential shaft staggered rewinding |

|

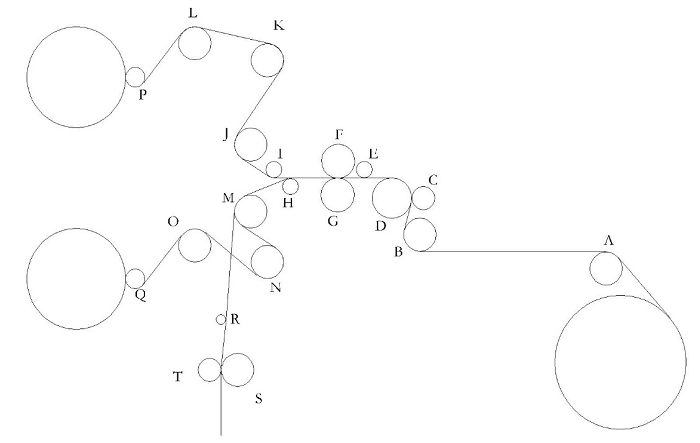

The coiled positive/negative electrode sheets after calendaring are loaded onto the unwinding system. Through driven traction, the electrode sheet is fed to a blade group arranged according to process specifications for slitting. The split sheets are rewound by upper and lower rewinding systems, while side trims are collected via a dedicated trim system. The machine is equipped with automatic web guiding, tension control, and dust extraction systems (including blade zone dust extraction) to ensure smooth feeding, stable slitting performance, and compliance with burr and straightness specifications.

Using a transfer trolley, load the material onto the unwinding shaft → splicing table → traction rollers → slitting blade group → roller group → upper and lower differential shafts → trim rewinding → set required tension → switch web guiding to auto mode → press start → the machine automatically slits and rewinds.

Approximate Dimensions:

· Main Machine: 1800mm (L) × 2300mm (W) × 1900mm (H)

· Dust Collector: 800mm (L) × 800mm (W) × 1400mm (H)

· Blade Cart: 1200mm (L) × 400mm (W) × 1000mm (H)

1.5.1 Unwinding System

|

No. |

Item |

Description |

|

1 |

Unwinder |

Single-shaft center unwinding; 3" core; Max. roll dia. 400mm; width ≤ 500mm |

|

2 |

Splicing Table |

Dual pneumatic pressing rod type |

|

3 |

Web Guiding |

Ultrasonic servo-guided; stroke ±40mm; accuracy ±0.2mm |

|

4 |

Tension System |

Fully automatic torque closed-loop control; adjustable 0–250N |

1.5.2 Slitting Mechanism

|

No. |

Item |

Description |

|

1 |

Mechanical Speed |

Max. 50m/min |

|

2 |

Slitting Speed |

0–40m/min |

|

3 |

Slitting Method |

Combined rotary blades; Nishimura-type structure; specs to be finalized |

|

4 |

Blades |

Material: tungsten alloy; Upper blade: Φ100×Φ65×0.7mm (35°), Lower blade: Φ100×Φ65×2.0mm (90°) |

|

Blade life: Positive electrode: 150–200k meters, Negative electrode: 250–300k meters; reusable 10x |

||

|

5 |

Blade Adjustment |

Adjustable blade clearance; engagement via screw threads |

|

6 |

Blade Drive |

Servo motor; adjustable blade speed percentage via control panel |

|

7 |

Cleaning Device |

Direct-discharge brush at lower blade |

|

8 |

Slitting Width Accuracy |

≤±0.1mm |

|

9 |

Electrode Snake Error |

≤±0.3mm/1000mm |

|

10 |

Metal Burrs |

Longitudinal: <6μm; Transverse: <10μm |

1.5.3 Rewinding System

|

No. |

Item |

Description |

|

1 |

Rewind Shafts |

Dual-axis staggered rewinding; slip-shaft; 3" core; Max. dia. 400mm; single loop 40mm |

|

2 |

Rewinding Accuracy |

≤±0.4mm |

|

3 |

Pressure Rollers |

Gravity rollers (75mm); pneumatic open/close; other sizes optional |

|

4 |

Dust Collection |

Dual brush cleaning (upper/lower); stepper-driven brushes; integrated ducting; blade zone extraction |

|

5 |

Edge Trim Unit |

Dual servo-driven systems; torque adjustable; trim >5mm; collected into bins |

|

No. |

Item |

Description |

|

1 |

Main Control Unit |

1. Rotatable centralized control panel; 2. OMRON main controller with Ethernet; 3. All key components are imported brands. |

|

2 |

Electrical Cabinet Layout |

1. Partitioned layout management; 2. Separate zones for mechanical, pneumatic, and electrical; 3. Electrical panel isolated from dust for ease of maintenance. |

|

3 |

Alarm / Maintenance |

1. Equipped with tri-color warning light and buzzer; 2. Visual and audible alarms for machine start-up/abnormalities; 3. Control interface includes IO check table. |

|

4 |

Electrical Specs |

1. 480V / 60Hz, 3-phase (US Standard); 2. Air consumption: 13 L/h; 3. Total power: approx. 6 kW |

|

5 |

Machine Uptime |

≥99% (web breakage rate <1%) |

|

No. |

Name |

Brand |

Origin |

|

1 |

PLC Unit |

Omron |

Japan |

|

2 |

Touch Screen |

Panel Master |

China |

|

3 |

Tension Control System |

Kruida |

China |

|

4 |

Web Guiding System |

Kruida |

China |

|

5 |

Inverter |

Mitsubishi |

Japan |

|

6 |

Low Voltage Circuitry |

Schneider |

France |

|

7 |

Inverter Motor |

CP |

China |

|

8 |

Servo Motor |

Mitsubishi |

Japan |

|

9 |

Stepper Motor |

Yankon |

China |

|

10 |

Pneumatic Components |

Airtac |

Taiwan, China |

|

11 |

Electro-Pneumatic Valve |

SMC |

Japan |

|

12 |

Proximity Switch |

DCF |

China |

|

13 |

Linear Guide |

PMI |

Taiwan, China |

|

14 |

Bearings |

NSK / Local |

Japan / China |

|

15 |

Planetary Gearbox |

Dexco |

China |

|

16 |

Coupling |

GZD |

China |

|

17 |

Differential Shaft |

Custom-made |

China |

|

18 |

Blades |

Shengong / Oulin |

China |

|

No. |

Name |

Model |

Qty |

Unit |

Remarks |

|

1 |

Hydraulic Blade Cart |

FT500 Special |

1 |

set |

|

|

2 |

Blade Assembly |

FT500 Special |

1 |

set |

|

|

3 |

Hydraulic Lift Cart |

FT500 Special |

1 |

set |

|

|

4 |

Pressure Roller Assembly |

70mm |

6 |

sets |

Others optional |

|

5 |

Upper Blades |

Φ100×Φ65×0.7mm |

10 |

pcs |

Others optional |

|

6 |

Lower Blades |

Φ100×Φ65×2.0mm |

10 |

pcs |

Others optional |

|

7 |

Blade Spacers |

19mm |

10 |

pcs |

Others optional |

|

8 |

Spacer Set |

TBD |

1 |

set |

Others optional |

|

9 |

Hook Spanner |

C32 |

1 |

pc |

For blade replacement |

|

10 |

V-Type Blade Base |

— |

2 |

pcs |

For blade replacement |

|

11 |

Dust Collector |

WHXC-2200 |

1 |

set |

|

|

12 |

Standard Tool Kit |

Hex keys, screwdrivers |

1 |

set |

|

|

13 |

User Manual |

— |

1 |

copy |

|

|

14 |

Accessory Manuals |

— |

4 |

copies |

|

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975