ItemNo :

LITH-PC-101MOQ :

1Port :

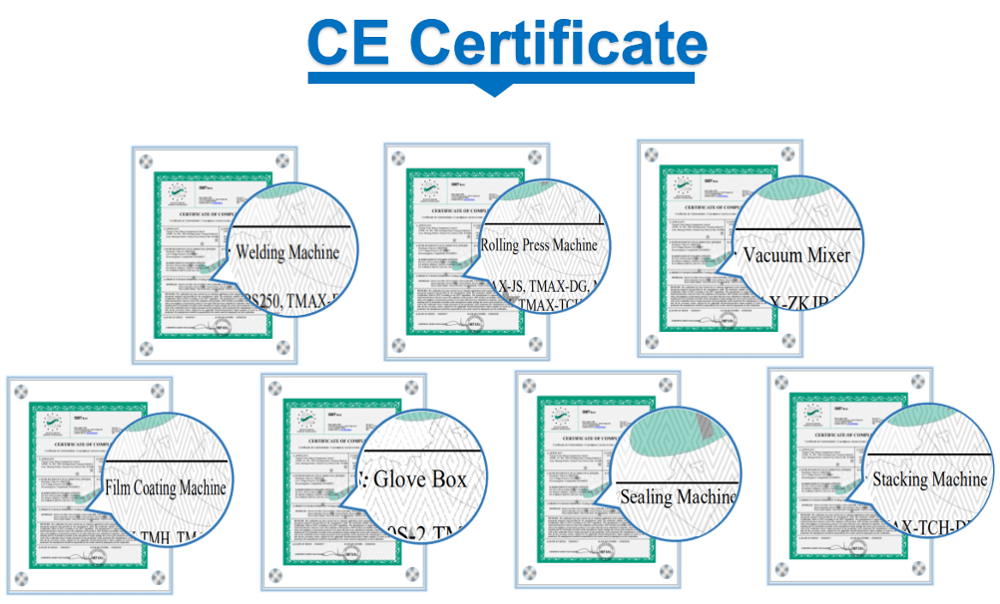

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comSemi-Automatic Production Line Prismatic Battery Pack Assembly Line

Product Introduction

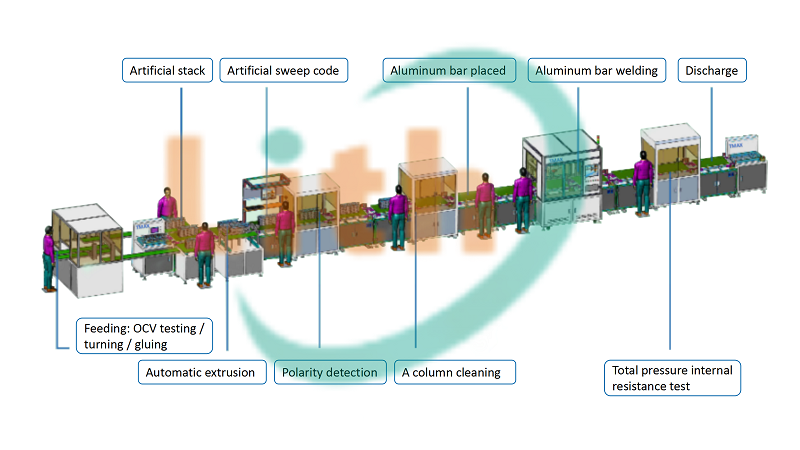

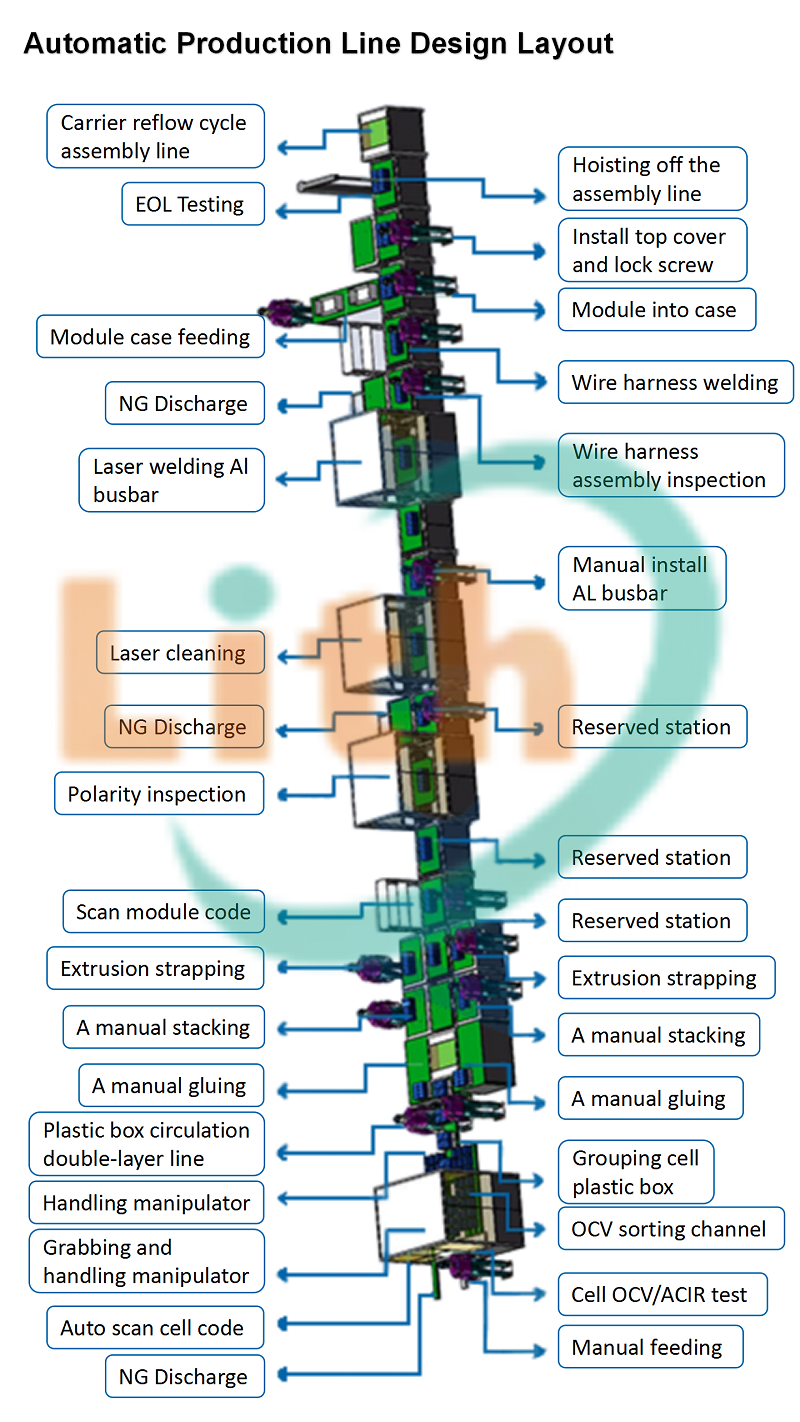

This customized production line is mainly used to complete the assembly, testing, and welding functions of the square shell energy storage lithium battery pack module, This semi-automatic line package includes manual feeding, cell scanning, automatic sorting, automatic flipping, automatic gluing, manual stacking, automatic extrusion, manual bundling, manual barcode scanning, binding, automatic polarity detection, automatic pole cleaning, manual placement of busbars, automatic laser welding, manual welding point detection, total pressure internal resistance testing of semi-finished products, manual offline, and automatic up and down reflux of empty trays.

General equipment configuration and standards:

1. The equipment is equipped with PLC and HMI communication interfaces, which can view the machine status and parameter settings

2. The appearance color of the equipment shall be based on the color palette provided by the customer (if the customer does not request it, the existing color palette shall prevail).

3. Measure at a distance of 100mm from the outer wall of the machine, and the equipment noise should be less than 80dB

4. The equipment shall comply with all safety standards and requirements required by the relevant national equipment safety standards and the buyer's safety regulations

Main Component brands List

| SN | Standard part category | Description of function and brand restrictions | Origion |

| 1 | Machine rack | Aluminum profile + sheet metal surface paint treatment | China |

| 2 | Processed parts | The surface of the aluminum parts is sandblasted and oxidized, and the iron parts are electroplated | China |

| 3 | man-machine | verenton | |

| 4 | PLC | Panasonic/Principal | Japan/China |

| 5 | Dispaly | Lenovo | |

| 6 | Industrial Computer | Advantech | |

| 10 | Power supply | Omron/Mingwei | |

| 11 | Sensor | Panasonic, Omron, AirTAC | Japan and Taiwan |

| 12 | Electric control accessories | Chint | |

| 13 | Contactor | Chint | |

| 14 | Button | ||

| 15 | Ordinary motor | Taijing | |

| 16 | stepper motor | Yingshida | |

| 17 | servo motor | Principal/Panasonic | |

| 18 | I/O board | Lei Sai | |

| 19 | cylinder, solenoid valve | AirTAC | Taiwan |

| 20 | bearing or linear bearing | NSK、FAG | Japan |

| 21 | guide rail | HIWIN、TBI | Taiwan |

| 22 | Structural standard parts | Yiheda |

This line mainly realizes the entire production process of square shell battery packs, with a total length of 16 meters. The entire line is composed of the following equipment combinations:

① Cell loading ② Battery pack bracket assembly ③ Battery pack Al Bar connector soldering ④ BMS circuit board soldering ⑤ Battery pack finished product inspection, etc. Multiple workstations are combined to form a complete line of equipment that can be linked or used alone. The interface is simple and clear, easy to operate, and easy to maintain. Each equipment has an independent control system and display screen.

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975