ItemNo :

LITH-OVENMOQ :

1Warranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com25L/50L 200C/400C Vacuum Oven with Digital Temperature Controller

Features

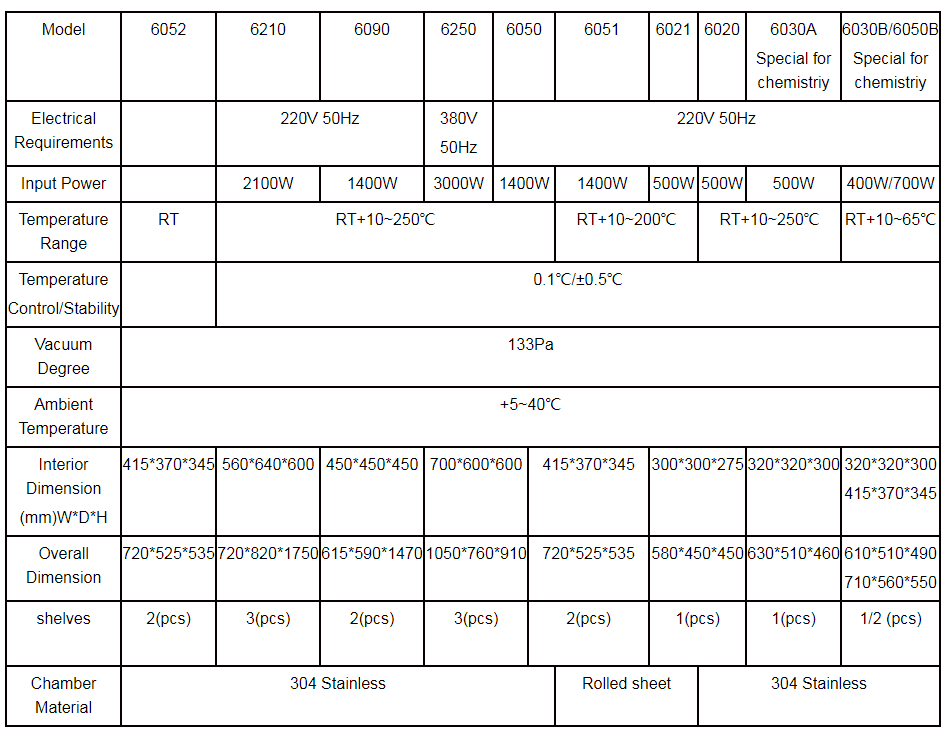

SPECIFICATIONS

|

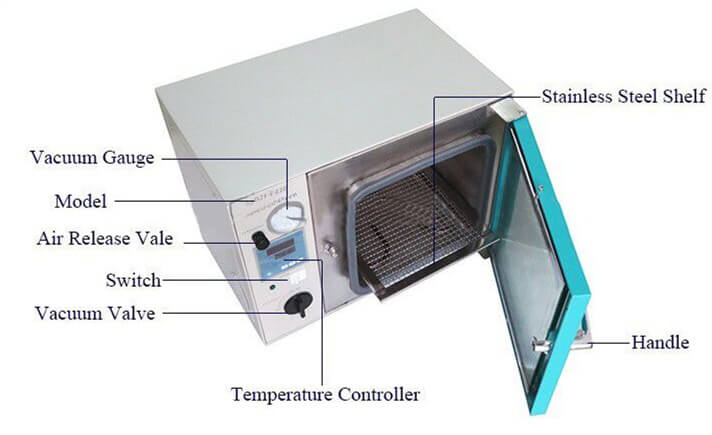

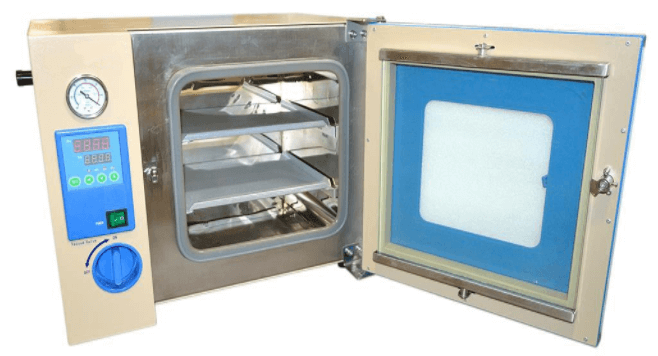

Chamber and Door |

1. The chamber is structured with stainless steel and welded to bracing pieces. |

|

Vacuum Pump |

Ultimate Vacuum Level: 1000 millitorrs. |

|

Working Voltage |

AC 108 - 240 V 50/60 Hz |

|

Input Power |

600W |

|

Working Temperature |

RT+10 ~ 200°C for the continuous use |

|

Temperature Controller |

1. Single point temperature setting |

|

Fittings |

This oven comes with a KF-25 vacuum connector which allows you set up a quick connection to the vacuum pump. |

|

Compliance |

CE Certified |

|

Warranty |

Two years limited warranty with lifetime technical support |

|

Attention |

1. It's normal that the SS chamber wall will slightly deform and loose its shine during high-temperature operation. However, this would not affect any functionality. |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975