ItemNo :

LITH-CS-05MOQ :

1Warranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

5 daysEmail :

Louis@lithmachine.com

SPECIFICATIONS

|

Max. feed size: |

10mm |

|

Final fineness: |

<100nm |

|

Min. sample quantity: |

10ml |

|

Max. sample quantity: |

1800ml |

|

Rotational speed (disk): |

50-400r/min |

|

Rotational speed (jars): |

100-800r/min |

|

Transmission ratio: |

1:-2 |

|

Transmission standard: |

CE |

|

Grinding modes: |

16 modes programmable |

|

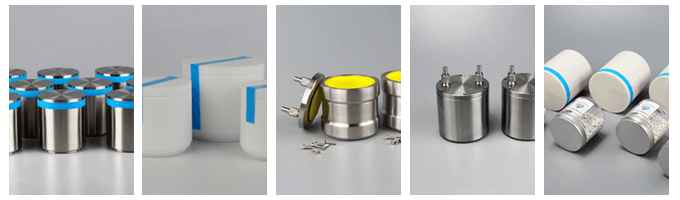

Grinding tools: |

grinding jars and grinding balls |

|

Bi-direction grinding: |

yes |

|

Continuously grinding |

00:01:00 - 99:59:59 |

|

Paused interval: |

00:01:00 - 99:59:59 |

|

Emergency stop: |

yes |

|

Power off memory: |

yes |

|

Overload protection |

Yes |

|

Milling chamber lighting: |

No |

|

Number of milling samples: |

4 simultaneously |

|

Materials of the grinding jars: |

SS304, SS316, nylon, PTFE, agate, zirconia, alumina, PU, WC |

|

Number of working stations: |

4 |

|

Ball mill type: |

horizontal |

|

Compatible grinding jars: |

50ml / 100ml / 250ml / 500ml / 1000ml |

|

Materials of milling balls: |

SS, agate, zirconia, alumina, nylon, PTFE |

|

Grinding ball diameter: |

3/5/10/15/20mm |

|

Compatibal ball weight |

400-2000g |

|

Grinding process: |

dry /wet grinding |

|

Vacuum grinding: |

yes |

|

Low temperature grinding: |

yes |

|

Grinding in inert gas: |

yes |

|

Temperature detection: |

yes ( special accessories) |

|

Pressure detection: |

yes ( special accessories) |

|

Electrical details: |

100-120V/200-240V AC ,50-60Hz, 750W |

|

Plug types: |

GB/EU/US/UK standard |

|

Net weight: |

140kg |

|

Dimensions (W x D x H): |

720*480*500mm |

|

Noise level: |

60dB |

|

IP rank: |

IP60 |

|

Product standard: |

CE |

|

Patent: |

design patent/ noise improve patent |

|

Accessories: |

user manual, warranty card |

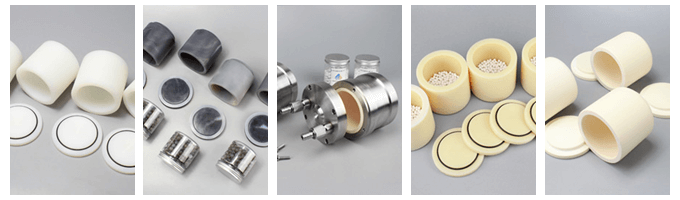

Material Data for Grinding Jars/Balls

|

Material |

Main component |

Density (g/cm3) |

Abrasion resistance |

Use for material to be ground |

|

Agate |

SiO2 |

2.65 |

Good |

Soft to medium-hard samples |

|

Sintered corundum |

Al2O3 |

3.8 |

Fairly good |

Medium-hard, fibrous samples |

|

Silicon nitride |

Si3N4 |

3.25 |

Excellent |

Abrasive samples, iron-free milling |

|

Zirconium oxide |

ZrO2 |

5.7 |

Very good |

Fibrous, abrasive samples |

|

Stainless steel |

Fe –Cr –Ni |

7.8 |

Fairly good |

Medium-hard, brittle samples |

|

Tempered steel |

Fe –Cr |

7.65 |

Good |

Hard, brittle samples |

|

Tungsten carbide |

WC |

14.95 |

Very good |

Hard, abrasive samples |

|

Polypropylene disposable jar |

MC/PA/PTFE/PU/HDPE/PP |

** |

Good |

For homogenisation |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975