ItemNo :

LITH-650MHMOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Introduction

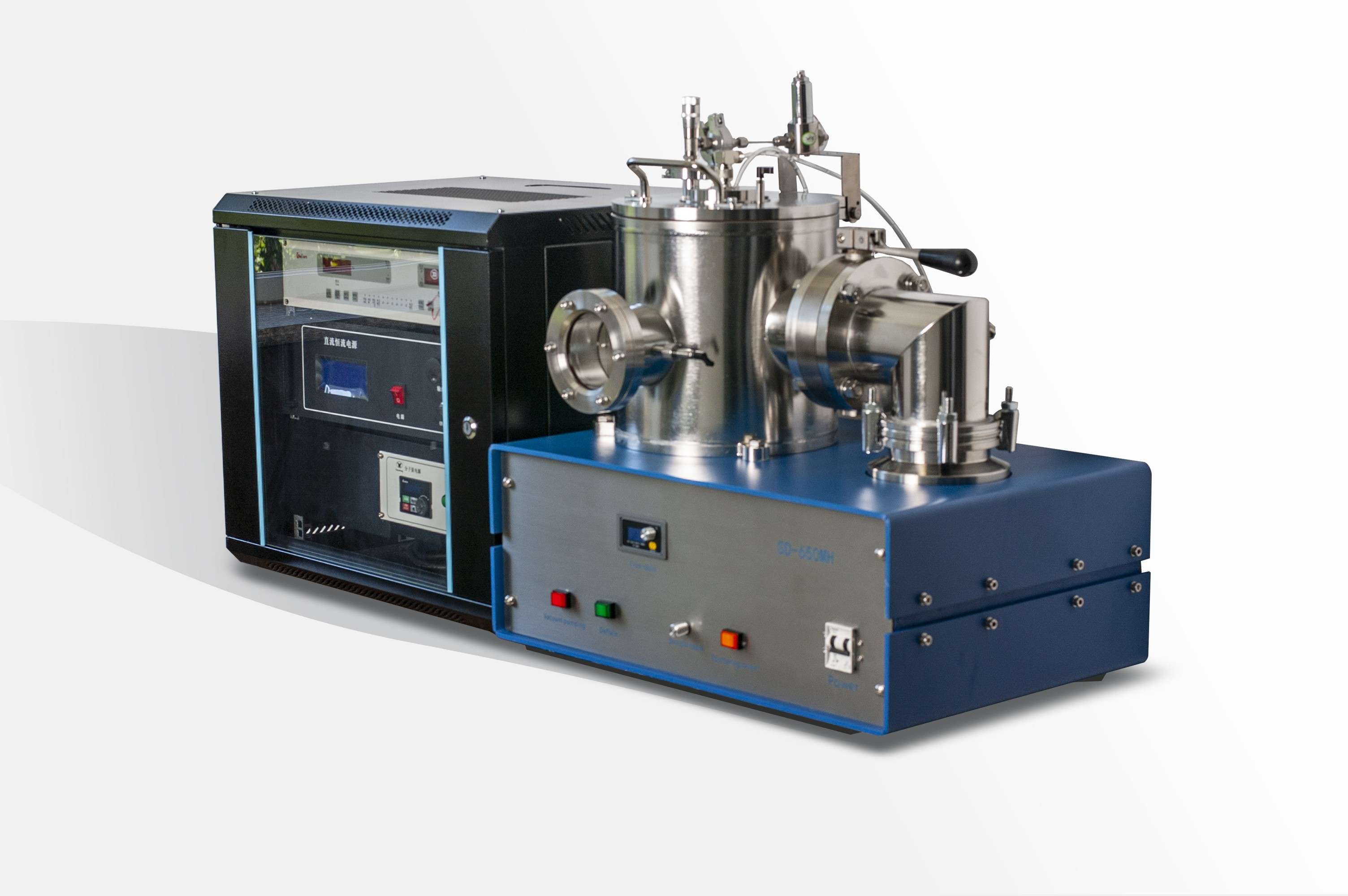

High Vacuum Magnetron Ion Sputtering Coater is ideal and designed for materials science and sample preparation. It is widely used for the majority of universities and scientific research institutes of materials science and engineering to coat, for metals, ceramics, semiconductors, insulators or other kinds of membrane material preparation.

High Vacuum Magnetron Ion Sputtering Coater provides the most stable sputtering environment and achieves the basic experimental conditions of magnetron sputtering in a very short period of time. It provides DC / RF two kinds of sputtering power options which allow sputtering conductive or non-conductive substance on specimen and improves physical vapor deposition (PVD) Performance. It is also excellent for surface treatment and coating. It is easy to operate and user friendly as well.

Vacuum pump and Chiller are included.

Parameter

Vacuum pump set

(Oil required) rotary vacuum pump+(oil free) turbo moleculan pump set

Rotary pumping speed

50 Hz : 16 m³/h (4.4 L/s)/ 60 Hz : 19.2m³/h (5.2 L/s)

Molecular pumping speed

300 L/s

Vacuum limit

5x10-5Pa

Working pressure

0.5-5 Pa

Vacuuming time

>10 Min(10-3Pa)

Vacuum measure

Measuring range from atmosphere to 1*10-6Pa

Gas control

Gas flow controller

Chamber size

φ260*200mm (height) metal

Magnetron target source

Target size φ 50*3mm(Cu)/target source: weak magnetic substance /materials

Operation method

Instruction Manual

Weight/size

100kg/610mm length x 420mm wide x 490mm high

Power supply

AC 110V 60Hz or AC 220V 50Hz

Power consumption

<3000W

Cooling method

Air cooling(pump)+ water cooling(sputtering target)

Warranty

One year limited warranty with lifetime product support

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975