ItemNo :

Lith-PTL15MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Features

Movements are achieved by a precision servo motor controlled linear stage that offers vibration and noise free operation. It helps to create a uniform coating on the substrate. The dip coating unit with infrared dryer has both manual as well as PC mode. In manual mode, a user friendly front panel with keyboard and LCD display is provided to enter all dipping and withdrawal parameters. As in PC mode, the entire unit can be controlled by user friendly software. It is also possible to save programs for future use.

Dip coating unit with infrared dryer has an infrared dryer incorporated with it, whose temperature can be set to a maximum of 200°C from ambient. This is meant for drying the substrate after the coating has been made. It has an infrared bulb inside,Dip oating unit with infrared dryer is mainly used in physics, chemistry and biotechnology labs and corresponding research activities.

Technical Parameter

|

Actuator |

Servo motor |

|

Drive mechanism |

Lead screw |

|

Speed control |

Drawing speed adjustable from the digital panel from 2 microns/sec to 9000 micron/sec ( Max.) |

|

Power Input |

110-240VAC, 50/60Hz |

|

Stroke length max. |

150mm |

|

Max Substrate size |

75mm x 75mm |

|

Control Unit |

1. Speed control via LED display with five programs memory |

|

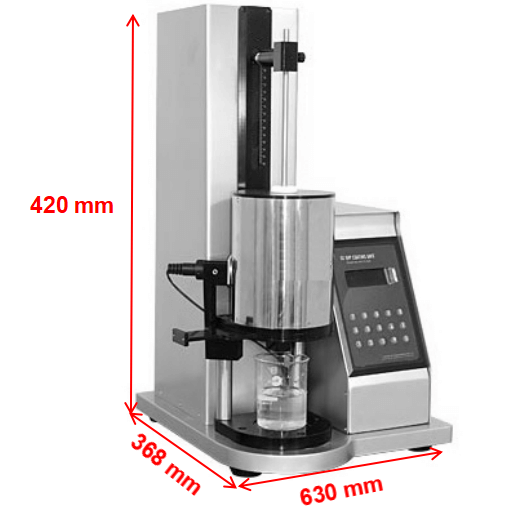

Product dimension |

630 x 368 x 420 mm |

|

Certificate |

CE Certified |

|

Warranty |

Two years limited with lifetime support |

|

Application notes |

1. to get better film coating, the substrate shall be treated by plasma cleaner |

|

Net Weight |

50 lbs |

|

Shipping Weight |

100 lbs |

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975