ItemNo :

LITH-EFQB-200MOQ :

1Delivery Time:

5 daysEmail :

Louis@lithmachine.com

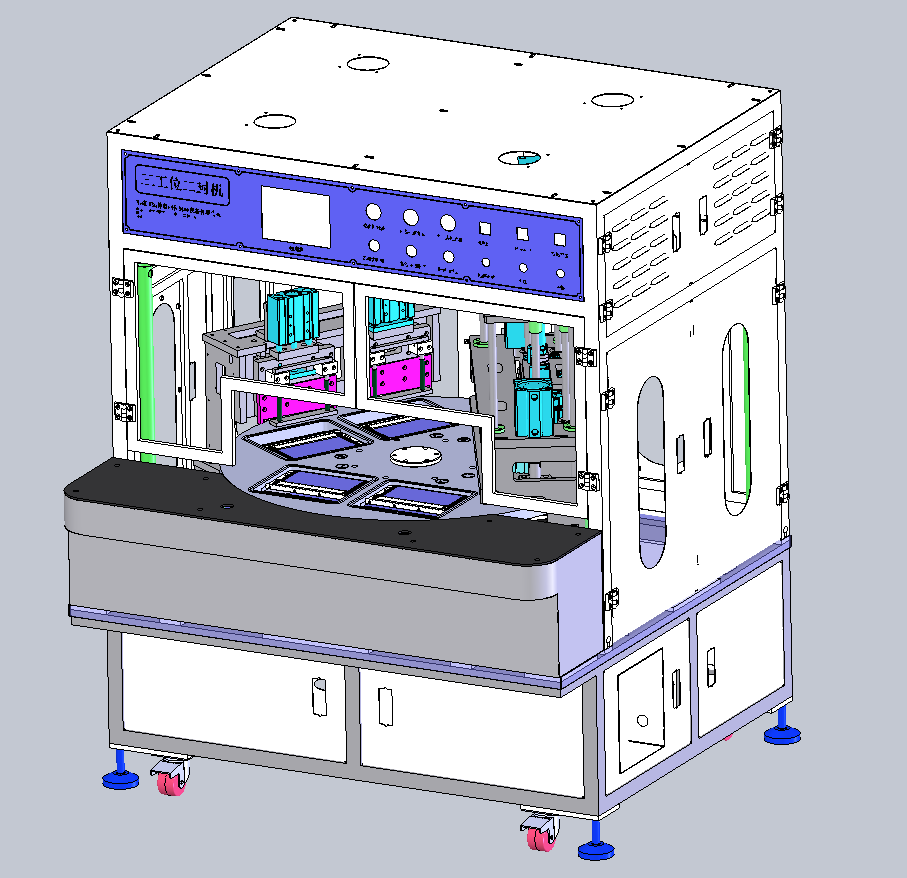

Pouch Cell Production Three-station Final Sealing & Edge Trimming Machine

This machine is suitable for the final vacuum sealing of lithium pouch cells and the removal of airbag edges. Manually place the battery cell on the turntable feeding mechanism. The battery rush direction is downward. Rotate the feed through the turntable. (The turntable puts 3 positions and rotates 120 degrees each time.) The feed turntable rotates into position and starts edge sealing. Enter the trimming station at 120 degrees to trim the edges. After trimming, rotate 120 degrees to return to the loading position, manually remove the material, and repeat the above operation.

Equipment structure

1. Adopting rotary turntable feeding structure, precision of turntable divider: ± 0.1mm

2. Machine package alignment accuracy: ± 0.1mm, head parallelism: ± 0.01mm

3. Sealing time adjustment range: 1s-30s, adjustment accuracy: ± 0.1mm

4. Heat sealing time and vacuum time are set on the touch screen: the packaging pressure is adjusted on the operation panel,

5. The temperature accuracy is controlled within the range of ± 2°C and controlled by the PLC program. If the temperature is too high or too low, the alarm will stop automatically

6. The package adopts double head and double cavity structure;

7. The heating tube uses 700 watts; the working temperature range of the head is RT~300 ℃;

8. The diameter of the upper head cylinder is 63mm, and the diameter of the bayonet cylinder is 25mm;

9. The doors and windows are made of sheet metal baking paint, and the exhaust fan is installed on the top;

10. The cutting airbag adopts a double edge cutter structure, each pair of edge cutters independently cut edges;

11. The cutting edge is made of wear-resistant and corrosion-resistant tool steel, and the life of the cutter is> 600,000 times;

Specifications

|

Power supply |

AC220V / 50Hz; Power: 4.5KW |

|

Compressed air |

0.4 ~ 0.6Mpa 20L / Min |

|

Applicable length |

≤200mm |

|

Applicable width |

≤120mm |

|

Airbag width |

≤70mm |

|

Double cavity double cutter |

Yes |

|

Piercing function |

Yes |

|

Flat pressing and shaping function |

Yes |

|

Effective length of cutter |

200mm |

|

Cutter width |

4.5mm |

|

Number of batteries that can be placed |

≤10 (dual cavity) |

|

Production capacity |

≤60 ~ 80PPM |

|

Equipment weight |

about 500Kg |

|

Vacuum source |

≤–95Kpa |

|

Dimensions |

1390 * 1240 * 1700mm (LxWxH) |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975