ItemNo :

LITH-SD200MOQ :

1Email :

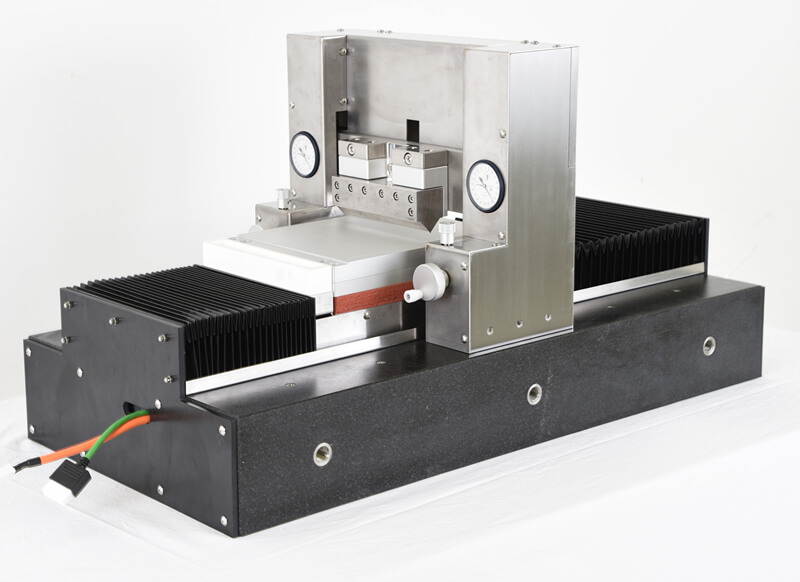

Louis@lithmachine.comBenchtop Precision Slot Die Coater for Thin Film Coating

Manual feeding on the coating platform (fixed by adsorption) - feeding system feeding die head - coating platform forward positioning - die head down positioning - start coating - coating system coating according to the set parameters - coating completion - feeding stop - manual product removal - completion

Equipment composition

1) Substrate positioning platform

2) Feeding system

3) Slit coating unit

4) Platform adsorption

5) Coating die position control, platform moving unit

Specifications

|

1. Basic parameters of base material |

|

|

Type |

Glass, silicon, flexible/soft sheet |

|

Thickness |

0.05~3mm |

|

Base material length and width |

Max.200mm W X 300mm L |

|

2. Coating parameters |

|

|

Coating thickness (dry) |

0.05-15um(for reference, actual depends on solution characteristics) |

|

Solid content |

10-70 |

|

Viscosity |

1-10000cp |

|

3. Basic parameters of the machine |

|

|

Coating method |

Slot die coating |

|

Effective width of coating |

Max. 200 mm; |

|

Coating platform speed |

0.06m-3m/min |

|

Coating platform |

250mm W*350mm L,Platform flatness: ± 0.05mm |

|

Power Supply |

220 V, 50 Hz |

|

Total power |

Max. 2 KW (with heating on) |

|

Air source |

0.6 MPa |

|

Machine dimensions |

Max. 1200mm L X 450mm W X 450 mm H(for reference, subject to final dimensions) |

Coating unit

|

Coating method |

Slot die coating |

|

Distance between die head and platform |

Fine adjustable range: 0.01-10mm Unit adjustment accuracy: 0.002mm Coarse adjustable range: 0-20mm With cleaning tank |

|

Die head (effective width 200 mm) |

included |

|

Platform driven |

Servo motor + ball screw + servo controller |

Platform adsorption / baking unit

|

Heating platform |

Al alloy, surface oxidation, accuracy 20μm |

|

Heater |

Electric heating components |

|

Heating temperature |

Temperature: RT-160 ℃, temperature control accuracy ≤± 3℃ (effective area: 200mmX300mm) |

|

Platform adsorption |

Aperture: 0.5mm , hole spacing: 25mm |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975