ItemNo :

LITH-1200PECVDMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com1200°C PE/CVD Furnace W/ RF Generator and Gas Mix & Pumping System

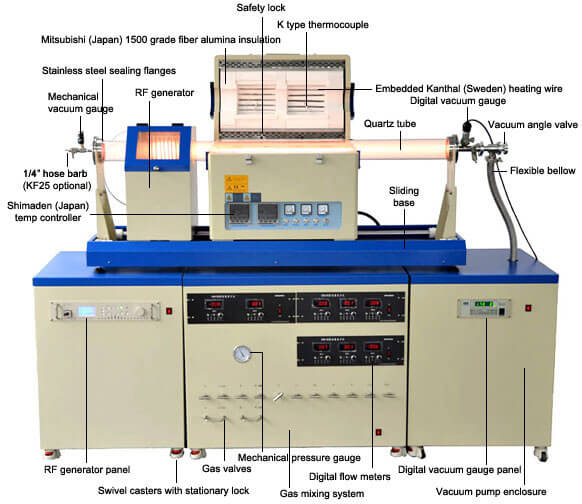

LITH-1200PECVD Chemical Vapor Deposition (CVD) and Plasma-Enhanced Chemical Vapor Deposition (PECVD) multi-zone split tube furnaces feature the famous Kanthal® (Sweden) wire heating elements embedded in high quality Mitsubishi® (Japan) alumina fiber insulation. All steel dual-layer housing ensures durability and helps minimize heat loss to exterior surface.

Furnace operation is controlled by Shimaden® (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results.

All our furnaces are CE compliant.

Features

1 Compact, portable and lightweight design.

2 Lower processing temperatures required compare to conventional CVDs.

3 Film stress can be controlled by high/low frequency mixing techniques.

4 Split furnace chamber for fast and easy tube access.

5 Standard package includes set of stainless steel vacuum sealing flanges with valves and pressure meter.

6 Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

7 Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

8 Built-in amp meter and dual voltmeters for easy monitoring and troubleshooting.

9 Built-in computer interface.

10 Long life type K thermocouple.

11 Slidable furnace option gives you ultra fast cooling rates

Safety

1 Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

2 Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

Warning! NEVER fill furnace with explosive gases, including Hydrogen, Carbon Monoxide and Methane.

Furnace, vacuum pump and gas mixing system specifications

|

Tube material |

Quartz |

|

Heating element |

Kanthal® (Sweden) resistance coil wire |

|

Max. vs constant working temperatures |

1200°C max. and 1100°C constant |

|

Thermo couple type |

K |

|

Refractory lining |

Mitsubishi® (Japan) 1500 grade fiber alumina |

|

Temperature controller |

Shimaden® (Japan) fp93 with 4 programs and 40 segments |

|

Maximum heating & cooling rate |

< 30°C / min |

|

Temperature controller precision |

+/- 1°C (+/- 1.8°F) |

|

Vacuum sealing flange kit |

Stainless steel vacuum sealing flanges with one vacuum gauge, |

|

Electrical requirements |

208-240VAC, 50/60 Hz, single phase |

RF generator specifications

|

Electrical requirements |

208-240 volts 50/60 Hz |

|

Output power |

5 to 500 watts, adjustable in +/-1% step |

|

RF frequency |

13 MHz with +/-0.005% stability |

|

Reflection power |

200 watts max. |

|

Matching |

Automatic |

|

RF output port |

50 Ω, N-type, female |

|

Cooling |

Air |

Standard Package

|

Part description

|

Quantity

|

Part image

|

|

split tube furnace |

1 set |

|

|

Multi-channel gas supply system |

1 set |

|

|

Plasma RF power supply (optional) |

1 set |

|

|

Vacuum pump and enclosure (optional) |

1 set |

|

|

Quartz tube |

1 pc |

|

|

Analog flow meter |

1 pc |

|

|

Stainless steel vacuum sealing flanges w/ pressure meter |

1 set |

|

|

Stainless steel hook |

1 pc |

|

|

Alumina ceramic thermal block |

2 pairs |

|

|

Thermal gloves |

1 pair |

|

|

Spare fuse |

2 pcs |

|

|

USB/RS485 computer interface kit |

1 set |

|

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975